E-commerce garment poor reviews,Get Consumer Demand

Bad Review Comment of CQI Inspection

Some garment and fashion companies have moved their industrial chains to Southeast Asia to save labor costs, but China’s garment industry chain is very complete, whether it is rich in oil resources, diverse and complete production processes, and sufficient industrial talents. Therefore it is still the one pick production place for many importers. We have summarized some of the commonly found bad reviews of clothing in e-commerce, plus CQI’s analysis of the reasons for these bad reviews and our points as a third-party inspection company in the factory inspection, hope it will be helpful to you.

Bad review

Only a few days to wear it, not getting it washed once, it has lost color.

Comments on CQI supplement

Some fabrics with poor color fixing ability do tend to lose color, such as cotton, linen, silk, special plants and animal fibers. Factories or suppliers need to communicate with customers in advance about this situation. In the actual CQI inspection, we will also check whether the garment is losing color by washing test.

Bad review

There is open seam, which affects the use.

Comments on CQI supplement

The appearance of open threads may be caused by the following two reasons:

1. poor quality of stitching, easy to break, worn out. 2. turner in the sewing jumped the needle.

This defective position a little larger may lead to an increasingly large open line.

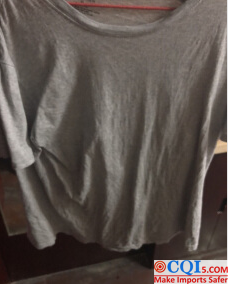

Bad review

It got so much smaller after being washed, is it that I grew taller? It is shrunken.

The white T-shirt has not been worn and it has been deformed to so long.

The T-shirt was washed and became larger.

Comments on CQI supplement

Deformation is definitely not allowed by consumers. Fabric shrinkage performance does not meet national standards to allow this to happen. Of course, unreasonable washing methods may also possibly lead to shrinkage and deformation.Therefore, in the daily inspection, CQI not only checks whether the garment is deformed through the washing test, but also checks whether the washing label meets the customer’s requirements.

However, objectively speaking, all fabrics will shrink. But the degree of shrinkage varies. And the fabric of natural fiber shrinks more compared to the chemical fiber, inorganic fiber, synthetic fiber. You can also understand that the sweat-absorbing and breathable fabrics are prone to shrinkage. Consumers should pay attention to this when shopping.

Bad review

Threads are everywhere, the workmanship is too poor.

There are pictures of the truth, not to say anything else, speechless.

Comments on CQI supplement

In the process of producing garments in factories, cutting the threads is a separate process. This step, together with ironing, ensures the appearance of the product.

When some factories omit these two steps in order to expedite shipments or save labor costs, they leave consumers with a much less favorable impression of the garment when they receive it.

CQI will record threads that are beyond the customer’s allowable length during the inspection.

Bad review

The clothes only wore a day to pilling. Super poor quality.

Just wear a few days, the clothes are all hairy.

Comments on CQI supplement

The winter sweater is actually normal because of the material pilling. But with poor fabric, the pilling will be very fast. Therefore, we will simulate the scene of consumer use during the on-site inspection, and conduct abuse test on the part that rubs more, and record it to our customers through pictures and videos.

Bad review

Just a few days after buying, the stickers on the clothes are falling off.

Comments on CQI supplement

Cheap, poor quality laminated screen printing will make the offset printing on the garment blister easily and even peel off. Digital offset printing is usually used only for better garments. This location is also the location that CQI needs to focus on during on-site inspection.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.