Hat Inspection Standards And Common Tests

1.Purpose

In order to clarify the inspection specifications and requirements of CQI Inspection Company for hat , this product inspection requirement is specially written to standardize the company’s quality inspection service level for customers.

2.Scope of application:

This inspection technical document is used to standardize the pre-shipment inspection service of hat .

3.Defect definition for hat inspection:

Serious defects (CRT): the user’s life is a major hazard or has the potential to harm and violate the relevant safety requirements of defects

Major defects (MAJ): affect the use of the product, reduce product reliability and service life or seriously affect the product image defects

Minor defects ((MIN): the product has a slight appearance defects and does not affect the product function defects

4.The level of inspection:

Sampling standards: MIL-STD-105E

Acceptance level (AQL): CR=O MA=1.5 MI=4.0

5.Common appearance and functional defects for hat inspection

(1) The stitch length must be kept between 3cm/10-12 stitches.

(2) the cap generally has a sweatband, the sweatband inside the non-woven paper has 70g and 85g, the color generally requires white, not yellow.

(3) the closure at the child’s band is generally at the outer entrance.

(4) pull sweatband must be flat suit; not cracked, especially the tongue part of the cap, the tongue pull line part of the needle code can not be too large.

(5) the top button has three corners and two corners, generally using three corners more. Top button should generally be able to withstand at least 15 pounds of tension.

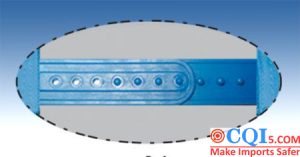

(6) rust eye must be played through, its color generally requires and the main color of the hat consistent;.

(7) the middle part of the front of the hat generally have embroidery and PVC label; its position requirements are generally in the lower mouth on 2cm-2.5cm, both sides centered, if it is embroidery, the requirements of its color must meet the requirements and can not leave a thread. If it is PVC label, it is required that its size must meet the requirements and cannot be warped and defective.

(8) When the whole ironing stitching parts must be flat, the temperature is generally required to be in 105 degrees -110 degrees, the time is generally in 7s-8s.

(9) the hat circle diameter size must be correct.

(10) When installing the cap tongue, its position must be centered, not skewed.

(11) The edges of the velcro are generally required to be trimmed to rounded corners.

6.Common Testing Items for hat Inspection

(1) color fastness test:

Woven strips of grass is dyed, woven fabric for the main material, fabric. Must do color fastness test, can be rubbed with a white cloth, (or alcohol cotton wipe), not to lose color, fading

(2) size measurement:

Hat has more than one size requirements

(3)Package security

(4) barcode test

(5)Tension test

(6)Abuse test

(7)Number of stitches per inch

(8)Odor check

(9)Color shading check

-within same piece

-among all inspected piece

(10)Adhesion Check for Silk screen printing/Coating

(11)Rub test on all marking or printing

(12)Rub test to check color fastness of the fabric and all accessories(i.e labels)

(13)General Function Inspection/Fitting check / Assembly test ( if any,)

(14)Abuse test/Fatigue test for all adjustable parts

(15)Barcode Scanning test

(16)Accessible sharp Point & Sharp edges check ( if any,)

7.Hat type and accessories

I. Baseball cap

II. bucket hat

III. Casual hats

IV. Tennis hat

V. Cowboy hat

VI. Children’s hats

VII. Fashion cap

VIII. Winter cap

IX. Knitted cap

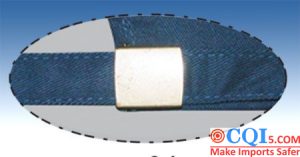

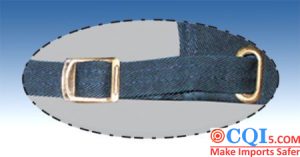

Accessories: PVC label, non-woven fabric, hangtag, cap tongue, buckle, Velcro, sweatband, etc. Such as.

6.Common defects of hats and test pictures

1)DEFECTS

2)TESTS

6.Summary

The above is the specific content of the hat inspection standard, but with the continuous development of the product manufacturing industry and the adoption of new materials and new production processes, new types of quality problems and new product testing requirements will directly result. Therefore, it is necessary to update the hat inspection standard irregularly.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.