What Is The Inspection Standard For Bathrobes Used Every Day?

Purpose:

In order to clarify the inspection specifications and requirements of CQI Inspection Company for Bathrobe products, this Bathrobe inspection standards requirement is specially written to standardize the company’s quality inspection service level for customers.

Scope of application:

This inspection technical document is used to standardize the pre-shipment inspection service of Bathrobe products.

Defect Definitionfor Bathrobe Inspection Standards:

Serious defects (CRT): the user’s life is a major hazard or has the potential to harm and violate the relevant safety requirements of defects

Major defects (MAJ): affect the use of the product, reduce product reliability and service life or seriously affect the product image defects

Minor defects ((MIN): the product has a slight appearance defects and does not affect the product function defects

The level of inspection:

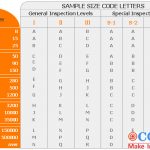

Sampling standards: MIL-STD-105E

Acceptance level (AQL): CR=O MA=1.5 MI=4.0

Common Appearance And Defects Of Bathrobe Inspection Standards

Poor Back-Stitches

Skip Stitches

Loose Stithces

Uneven Woven Fabric

Uneven In Length

Stain

Thread Ends

Poor Sewing

Poor Dying

Common Testing Items For Bathrobe Inspection Standards

(1) Size and weight check

Size: in accordance with the requirements of the order, the difference in length and width does not exceed 3-5%.

Weight: in accordance with the requirements of the order, with a deviation of not more than 3% up and down.

(grams ≥ 100g single weighing, grams < 100g, 10 weighing)

(2) Color check

Use of violet light irradiation, translucent check for fluorescence, other stray light.

Dyeing without obvious color difference color flower, no wrong color, no color loss, printing effect does not affect the appearance.

(3) Sensory inspection

Surface: yarn count without broken warp, broken weft, edges without burrs, rolled edges, tooth edges, neat terry, no brittle fiber damage.

Sewing: no obvious threads, no skipped stitches, no stripped threads, sewing without errors

Shaping: flat, no weft slanting, consistent size on both sides required

Towel texture / feel: poor feel no elasticity, no natural softness (different from putting softening powder), a sense of wood solid (poor quality of cotton material)

Foreign matter and stains: no miscellaneous yarn and cotton balls mixed in, no oil, color stains

Odor: whether there is a significant odor in the unboxing and sampling test.

(4) Tensile fracture test

Pull all parts of the towel under strong tension to check whether there is fracture and rupture.

(5) Water absorption test

Put the test sample of 5cm×5 cm into 800mL tertiary water with water temperature of (20±2)℃, water temperature of 21℃, water level height of 7 cm, test the absorbency of front and back side of Bathrobe before and after washing, and record the time of its complete wetting.

(6) Grammage test/GSM

A specified area of Bathrobe was cut using a cutter and the gram weight per square meter was measured.

(7) Color fastness test

Washing: Soak the Bathrobe in water and rub it back and forth 10-20 times simulating daily life to check whether there is color loss and floating hair.

Soap wash: soak in soap solution and simulate daily life scrubbing back and forth for 10-20 times, continue to rinse in warm water at 40℃ for 3 times, 1min each time, check whether there is color loss, floating hair.

Color Bathrobe warm water soaking: rub towel 5 minutes, 70 degrees warm water soaking 30 minutes, check whether there is color loss, floating hair situation.

(8) Test for leaving pile

Cut pile Bathrobe: cut the Bathrobe with a sharp blade, check whether the towel is easy to lose pile in the cutting process.

(9) Length check

For the long pile model Bathrobe, use the measuring instrument to measure the length of the pile.

(12) Sewing density test

Use a measuring instrument to measure the metric weight (g) per kilometer (km) of yarn (or monofilament).

(13) Abrasion resistance test

Rub the Bathrobe back and forth on a rough surface 20-50 times to check the degree of abrasion of the towel surface during the process.

(14) Packaging inspection

Outer box printing, including side mark, positive mark, inside and outside bag, paper card and trademark label printing, correct in color, text spelling, direction number; carton shall export double corrugated or triple corrugated carton, flat and thick, no damage to carton, no moisture, no deformation; goods should be filled without gaps; inner packaging materials are good, plastic bags must be clean, transparent and strong; both internal and external packaging are free of deformation, damage or stains.

Summary Of Bathrobe Inspection Standards

The above is the specific content of the Bathrobe inspection standard, but with the continuous development of the product manufacturing industry and the adoption of new materials and new production processes, new types of quality problems and new product testing requirements will directly result. Therefore, it is necessary to update the Towel inspection standard irregularly.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you