Check!Computer Desk Inspection Standards

1.Purpose:

In order to clarify the inspection specifications and requirements of CQI Inspection Company for Computer desk , this product inspection requirement is specially written to standardize the company’s quality inspection service level for customers.

2.Scope of application:

This inspection technical document is used to standardize the pre-shipment inspection service of Computer desk .

3.Defect definition for Computer desk inspection:

Serious defects (CRT): the user’s life is a major hazard or has the potential to harm and violate the relevant safety requirements of defects

Major defects (MAJ): affect the use of the product, reduce product reliability and service life or seriously affect the product image defects

Minor defects ((MIN): the product has a slight appearance defects and does not affect the product function defects

4.The level of inspection:

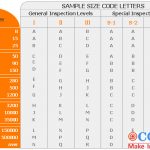

Sampling standards: MIL-STD-105E

Acceptance level (AQL): CR=O MA=1.5 MI=4.0

5.Appearance structure requirements

(1) The product surface color should be the same as the color of the sample provided, no color difference.

(2) The appearance of metal parts should meet the following requirements:

a.No delamination of the stamping parts;

b.The difference between the height of the wrinkle at the bend of the round and flat line pipe should be no more than 0.4mm, and the arc at the bend should be round and smooth;

c.Weld scar surface ripples should be uniform, the difference between high and low should not be greater than 1.0 ;

d.The weld should be free of slag, porosity, weld tumor, wire head, biting and spatter;

(3) In contact with the human body or collection of goods shall not have burrs, edges or angles;

(4) welding should be no desoldering, false welding, welding through;

(5) the yoke should be free from leakage of kushion, off key .

(6) coating (plating) layer should be no flaking, rust and sticky paint.

(7) The exposed parts of the plating layer shall not have scorching, blistering, exposed bottom, pinholes, cracks, flower classes, obvious scratches and burrs.

(8) metal parts paint film coating shall not have exposed bottom, bump, lump, wrinkle, flying paint, color difference, obvious flow hanging pattern defect;

(9) Wooden film coating should be free of powder accumulation, slag, leakage of putty, brush hair, edge, shrinkage, color difference, over fluting, hanging, Zoupi, white spots and obvious particles;

(10) The surface appearance of wooden parts should meet the following requirements:

a.The outer surface chamfering, rounded corners rounded line should be consistent;

b.The use of various artificial board parts should be sealed edge treatment, edge sealing strip does not allow degumming, bulging.

c.Opening and closing accessories should be flexible, folding products should be folded flexibly, there should be no self-folding phenomenon.

d.The parts of the product should be fastened without loosening, and the connectors for the installation of the exchangeable parts should be reliably connected.

6.Common Testing Items for Computer desk Inspection

(1)Main dimensional measurement of products

a.The height difference of the main table, table, chair supporting products Height increase board, main machine board, key plate board

b.The net distance between the build plate and the table surface

c.keyboard board in and out of the requirements of the activity freely, there shall be no jammed unpleasant feeling.

d.keyboard board pushed into the edge of the panel shall not exceed the edge.

c.Roundness

d.Round tube bend

(2)Welding requirements

welding place should be no desoldering, false welding, welding through.

(3)Kushion connection requirements

Kushion joint should be free of leakage, de Kushion

(4)Coating requirements

The coating should be free of flaking, rust and sticky paint.

(5)Safety requirements

There shall be no protruding burrs or edged angles at the parts that contact human body or collection items.

(6)Stability test

The deviation of the stability of the foot of various products on the ground shall be no more than 2.

(7)Wood moisture content requirements

Should not exceed the average annual moisture content of wood in each region plus 1%;

(8)Pipe and stamping requirements

Pipes and stampings shall not be allowed to have cracks and excessive raw edges HV0. 2;

(9)Metal parts appearance requirements

①Pipe requirements

1) stacked seams; 2) welding without misalignment; 3) no scars

②Stamping parts requirements

1) no delamination; 2) the height of the corrugation at the bend of round and shaped pipes is not more than 0.4; 3) the arc at the bend should be rounded and smooth.

③Welding parts requirements

1) weld scar surface ripple height is not more than 1; 2) no slag; 3) no porosity

4) no weld tumor; 5) no edge gnawing; 6) no spatter.

④ Unloading requirements

1) unloading nail head round; 2) end square no kushion mark

7.Summary

The above is the specific content of the Computer desk inspection standard, but with the continuous development of the product manufacturing industry and the adoption of new materials and new production processes, new types of quality problems and new product testing requirements will directly result. Therefore, it is necessary to update the Computer desk inspection standard irregularly.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.