Knitwear Inspection,The Defects Consumer 0 Tolerance

The knitwear has a wide range of styles and has a good warm-keeping function. It is the best choice for most consumers when the temperature is cold. When international importers import garments in China, the requirements for fabrics& design, processing technology and knitwear inspection standards are often more stringent because of the characteristics of knitwear because of the characteristics of knitwear .

The basic process of knitwear is roughly as follows:

Ordering the wool – weaving – checking fabric – sewing – hand stitching – lighting & checking and mending – washing – ironing – marking – Initial checking – mending – re-checking – final checking – ironing – hanging tags – packaging .

Each step in the process is processed according to the importer’s product requirements, and after each step, a number of inspections will be carried out in order to control the product quality to meet the quality requirements and smoothly to the next step. Before shipment, importers will appoint a third-party inspection agency to carry out knitwear inspection as the final guarantee of supply chain safety in China. Please check for details Inspection before shipment .

Knitwear Inspection Requirements

I. Appearance Inspection

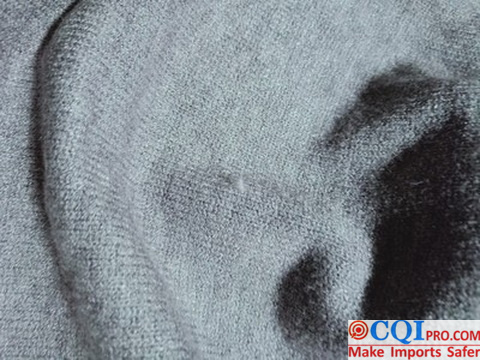

Whether there are stains, color differences, thread ends, fuzz and breakage on the surface of knitted products, and whether the surface threads are smooth and equal;

Whether the quality of the cloth is qualified, without any color difference, shrinkage and other defects;

When checking the size, whether it meets the size requirement according to the size table;

Whether the collar size and collar bone of the knitwear are symmetrical, the width of the two shoulders and the two loops;

Whether the length and width of the two sleeves, the two sides are symmetrical.

II. Workmanship Inspection

Check whether the lines of all parts of the product are straight, neat and firm, and there can be no floating lines, broken wires, jumpers, etc. and the needle spacing cannot be too thin or too dense. Whether the neckline meets the standard requirements, whether it is skewed, uneven, wavy, etc. Whether the buttons and buttons are positioned accurately and symmetrically, whether the buttons are flat and have no loose openings, whether the buttons are strong and not too loose and too long, etc. We know that the quality of workmanship of knitwear products directly affects the function of the products, so workmanship inspection is the top priority in knitwear inspection.

Ⅲ.ironing inspection

The function of ironing is to ensure the finished clothes are even, but after ironing, pay attention to whether they are free from yellowing, aurora, water stains, dirt, etc.

IV. Material Inspection

Material inspection means that the product in knitwear inspection is inspected according to the instructions of the bill of materials, to check the shipping mark,sewing effect and the labels, such as whether the certificate clearly indicates the commodity information, without any omissions, etc.

Ⅴ.packaging inspection

When packing, fold up the clothes and pack them in strict accordance with the standard of the packing instruction.

Summary On Knitwear Inspection

Qualified factories have certain inspection guarantee after each process step. In the knitwear inspection of the finished product, mass production are inspected according to the standard of sampling inspection Random sampling can once again verify the quality level of the whole bulk goods.

Although the process flow and inspection standards of each supplier or factory may differ slightly according to actual needs, they are also similar. Therefore, when follow up the samples and mass production, suppliers and importers may employ a third-party inspection agency to communicate with relevant departments or personnel in real time and properly handle and resolve the problem in the production, reducing the losses of both sides of the trade. Want to know more about it, pls check What are the advantages of outsourcing inspection.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.