Hair Dryer Quality Inspection,Share With You More Details

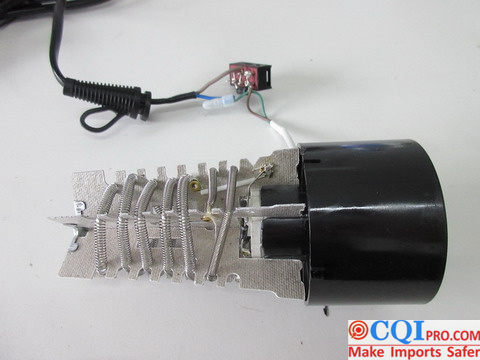

In the era of ” black technology” of hair dryers, negative ions and water ions hair dryers emerge one after another, but the high prices are beyond reach. Many people will still choose cheap hair dryers, although the prices vary greatly, but the structure is the same, except that big brands of hair dryers have added special functions and can clearly detect the differences when carrying out hair dryer quality inspection. The common hair dryer is composed of a shell, a handle, a motor, blades, an electric heating element, a wind shield, a switch, a power cord and so on.

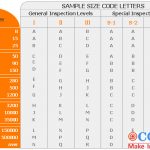

Hair Dryer Quality Inspection-Structure

1.Shell: It protects the internal parts and is also an external decorative part.

2. Motor and fan blade: The motor is installed in the housing, and the fan blade is installed on the shaft end of the motor. When the motor rotates, air is sucked in from the air inlet and blown out from the air outlet.

3. Electric heating element: The electric heating element of the electric hair dryer is wound with electric heating wire and installed at the air outlet of the electric hair dryer. The air discharged by the motor is heated by the electric heating wire at the air outlet and sent out into hot air.Some hair dryers are fitted with thermostats near the electric heating elements, and when the temperature exceeds a predetermined temperature,the circuit is cut off to play a protective role.

4. Windshield: Some hair dryers have circular windshields at the air inlet to regulate the air input.For hair dryers without a circular wind shield, a piece of paper can be used to cover a part of the air inputand also adjust the air inputIf the air input volume is small, the blowing wind will be hotter, and if it is large, the blowing wind will not be too hot.

5. Switch: Electric hair dryer switches generally have ” hot air”, ” cold air” and ” stop” positions.

Hair Dryer Quality Inspection-What To Focus On

When consumers buy hair dryers in shopping malls, most of they try them simply to check whether the cold and hot air is normal, whether there is noise, whether there is peculiar smell, etc.There almost no any concern for safety performance, so small factories seized the opportunity to make money and immediately put into the production of cheap hair dryers. But what parts of the dryer can be cut corners on? First of all, the power cord, which is a part that is easy to use secondary materials, will soon become hot and soft after the power supply is turned on due to its long service time and aging phenomenon, plus some wires are too thin.Moreover, many products with power higher than 2000 watts are equipped with three-hole plugs with grounding function, all of which are easy to cause spontaneous combustion. Therefore, when hair dryer quality inspection is in progress, the thickness of the power cord and the identification on the line are also one of the key points for inspection.

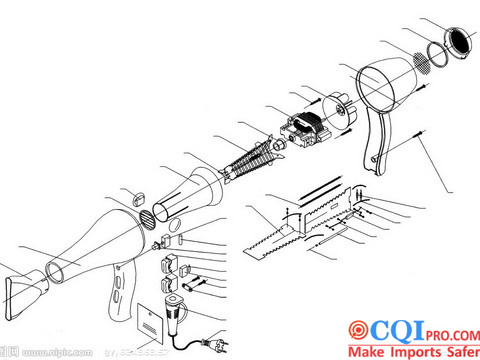

In hail dryer quality inspection, the product needs to be disassembled. Because the core components of the hair dryer are motors and electric heating elements, if the black heart factory uses old wires and old copper sheets, the products will obviously heat up and even produce burning smell after the power supply is turned on, and the risk factor is very high. Good quality hair dryers use two or three sections of heating wire to adjust the temperature.Of course,the black heart factory will try any ways to save money. It is already their ” kindness” to use a section of heating wire. Otherwise, the best material for them is the secondary material. Then, the problem that follows is how to avoid the use of secondary materials. Buyers can arrange third-party inspections in the early and middle stages of product production. In Intitial Productial Inspection and During Production Inspection, you can learn the content and significance of the inspection in detail.

Low – end hair dryers often cause disturbances in society. Once there was a news that a consumer bought a cheap hair dryer and was glad to think she had got a bargain at first. However, when she used the hair dryer, she was shocked to find that smoke was come from the nozzle and even a flame soon after. Fortunately, the lady did not point the nozzle at herself, only a slight scald on her hand and the toilet full of smoke smell. Once the problem is discovered, the product has been taken off the shelf. If hair dryer quality inspection can be carried out before it is sold, it will probably not happen. This terrible hair dryer killer needs consumers to be careful. Do not buy the cheap and be cautious, which will avoid the tragedy.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.