Container Loading Inspections,Helps You Receive Your Goods Smoothly

In international trade, importers usually entrust a third-party inspection company to carry out container loading inspection in order to avoid the exporter intentionally or unintentionally loading less quantity or mispacking the purchased goods when loading the goods into containers, and to avoid the brutal shipment of goods in the process of packing and ensure that the exporters loading the goods in strict accordance with the requirements.

Although container loading inspections is a very common inspection service in international trade, many importers only know it but didn’t understand how and why. So this article will elaborate on the 7 aspects that importers most want to know, so that you can read the container loading inspections in one article.

What is container loading inspections?

Container loading inspections, also known as loading supervision. Through professional inspectors to carry out container inspection, product inspection and product quantity inventory at the loading site, supervise the on-site product handling, etc., to ensure that the shipped items reach the destination safely and completely.

Why do you need a third party for container loading inspections?

In communication with many familiar customers, it is found that their understanding of container loading inspections remains on the surface, and it is believed that there will be no risk during the process of container loading, and the container loading inspections is only a simple supervision of on-site goods carrying. In fact, otherwise, any problem in any part of the container loading will cause greater losses. If the loading method is not appropriate, various situations may occur such as wrong loading, less loading, wet goods, damaged outer cartons and so on.

In order to ensure the good receipt of goods, the supervision of container loading is an essential link. Loading goods under the supervision and guidance of a third-party inspection company can avoid the defects caused by improper loading methods, and avoid intentional or unintentional mistakes such as under-loading and wrong loading, so as to ensure that the goods you received are in the same good condition as when they were delivered.

For example, a customer of CQI Inspection Company complained that his supplier didn’t pay attention when he pick up the container, and when such a container was transported by sea or in rainy days, the water entered the container, and the product was damaged, which eventually caused huge losses. If the customer had a third party to carry out container loading inspections at that time, the inspector would immediately check the damage of the container when it arrived at the scene, and if the container was damaged, CQI inspection company would immediately notify the customer, thus completely avoiding such losses.

In the process of container loading inspections, the account manager of CQI inspection company will continue to follow up the on-site situation. When problems such as incomplete product quantity, product quality problems, product names inconsistent with the list provided by customers are found, the account manager will immediately feed back the on-site problems to customers to confirm whether to load as usual, so as to avoid risks from every detail.

What are the differences in the process of container loading inspection?

Undoubtedly, price must be one of the most concerned issues for every customer. Faced with various inspection companies in the Chinese market, prices are also different. So, in such a big environment, how to choose a suitable inspection company is particularly important. Many importers ask such a question: Is there any difference in the container loading inspections process of each inspection company? Is it necessary for me to find a high-priced inspection company?

From the scale of inspection companies, there are three types: large, medium and small inspection companies.

Most of the large-scale inspection companies are multinational companies. After a long period of precipitation, they have their own brand effect and have accumulated a large number of customers. Most of their customers are large supermarkets and large suppliers with stable and long-term cooperation. It is precisely because this kind of large-scale inspection company has its own brand effect, and the charging is relatively high, and the cost of container loading inspections reaches more than 380USD.

I believe many customers can accept the higher loading inspection cost, if this can bring a higher standard of service, but it is also because the large inspection companies have a long history and have formed their own container loading system for so many years, and the loading process of each inspection company is similar, so inspectors only need to follow the rules and complete their workload step by step. Such container loading inspections does not have its own core competitiveness. Do suppliers just want to pay a high price to buy a company logo on report of inspection company?

I believe many customers can accept the higher loading inspection cost, if this can bring a higher standard of service, but it is also because the large inspection companies have a long history and have formed their own container loading system for so many years, and the loading process of each inspection company is similar, so inspectors only need to follow the rules and complete their workload step by step. Such container loading inspections does not have its own core competitiveness. Do suppliers just want to pay a high price to buy a company logo on report of inspection company?

In addition to large inspection companies, domestic small and medium-sized inspection companies have also developed with the rise of international trade in recent years. The leaders of such companies usually have experienced inspection, who have worked hard in the inspection industry for decades, and are well versed in the rules and significance of inspection. Generally, this kind of company is small in scale, with about 100-200 employees and 200-250USD in price. With the idea of serving old customers well, it builds its own brand in every detail. Taking CQI Company as an example, according to the different needs and particularities of different customers, different key points of loading containers are formulated, and inspectors on site are responsible for following up on-site loading cases and feeding back problems to customers in time.

A few years ago, a new Russian customer of CQI Company used the container loading inspections service of a small company before finding CQI Company. However, after receiving the goods many times, it was found that the total quality was less than order. This Russian customer couldn’t understand why the quantity was still wrong under the supervision of a third-party inspection company. Is this the problem of the inspection company or is the container loading inspections service just a superfical process and useless? However, the container loading inspections service is the only service that can solve the problem of shortage of goods. Russian customers have no choice but to try the container loading inspections service of other inspection companies.

Therefore, this Russian customer came to CQI company to find a way to solve the problem and prevent this kind of situation from happening again. According to the feedback of this customer’s problem, CQI inspection company held several meetings to discuss the cause of the problem and revised the loading plan several times, then provided the final plan to the customer. For this customer’s container loading inspections, the account manager of CQI Company will constantly confirm various matters of loading conditions with its suppliers in advance. Because of the particularity of this container loading, CQI Company ask factory to arrange containers to arrive at the site as soon as possible, and inspectors speed a lot of time to complete the loading plan of the company. The inspector not only counts on the spot, but also takes pictures of all sides of each pallet to ensure that the quantity of each pallet can be counted from the report picture.

CQI company also provides a specially formulated counting table,inspector and warehouse keeper take one copy and count separately,signed and sealed after data is cross checked. Finally, each tray is taped with film and affix the label of CQI company. The account manager of CQI company will review the inspector’s report ,count the number twice through the picture to ensure the accuracy of the number. At the same time, in the presentation of the report, the classification of pallets is clear, and the number of comment pallets is clear, so customers can intuitively count the number of products on the report. Up to now, CQI Company has cooperated with this customer for 6 years, and during this 6 years, there has been no shortage of goods in containers, and various processes have been continuously optimized. The customer said that it was CQI company that made him trust the third-party inspection again. In CQI company, there are countless cases of making special plans for customers, aiming at customer satisfaction, and doing every inspection and container loading inspection with care.

If you want to pursue low prices blindly, there are also many small inspection companies on the market for you to choose from. The price of such inspection companies is usually around 100USD. Because of the low price, the inspectors usually employed are not highly educated, and the company will not spend a lot of time training inspectors. There is no macro consideration on the loading site, and there is no awareness of controlling the loading risks in advance.

Whether it is a large, medium or small inspection company, the purpose of container loading inspections is to ensure the safe and complete arrival of the goods. Choose a good inspection company, not from the price and brand, but from the company’s service concept; if can consider all from the customer’s point of view, it is a trustworthy inspection company.

What are the types of containers?

Container is an essential transportation equipment in the process of loading containers, which has rigidity and strength and can be used repeatedly.

Containers can be divided into:

- Dry storage container

- Open-top containers

- Flat rack containers

- Ventilated containers

- Bulk containers

- Animal containers

- Tank containers

- Car containers

- Hanger containers are also called hanger containers

Classification according to main materials:

- Steel container: ordinary container

- Aluminum container: such as refrigerator

- Stainless steel container: tank container

Next, we mainly introduce several commonly used containers:

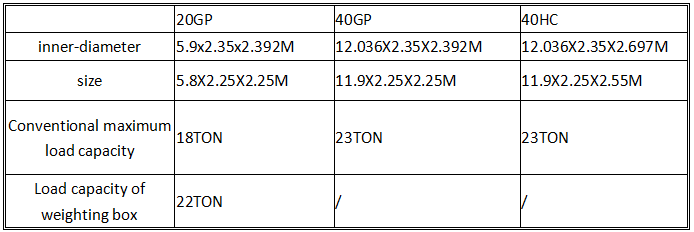

1.Dry storage container is the most common standard container, which can transport as many kinds of goods as possible and is the most widely used container. Dry storage containers are divided into 20GP,40GP and 40HC by volume. the characteristics are as follows:

2.Open-top container:

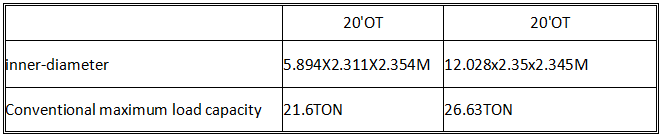

Open-top container, also known as open-top container, is a special structure container without rigid top. In order to prevent wind and rain, the top is covered with canvas, plastic cloth or plastic-coated cloth supported by the top beam. Other structures are similar to those of ordinary containers. However, this type of container only tries to be not super high, but the cargo volume is relatively large, and it is inconvenient to load and unload through the cupboard door and needs to be hoisted, or super high large cargo.

It can be divided into 20’OT and 40’OT by volume. The container features are as follows:

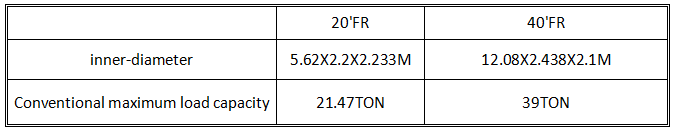

3.Flat rack container:

Flat rack container is a kind of container which has no top and wall, and the end wall can be removed, leaving only the bottom and four corners to bear the load. This kind of container is mainly used for heavy, large and different shapes of goods such as large pieces, overweight pieces, light soaked goods, heavy machinery, steel, steel pipes, bare equipment, etc., which are not suitable for loading into ordinary containers or open-top containers.

The above is a brief introduction to the types of commonly used containers. Choose suitable containers according to different product types, but during the specific loading, the following matters should be paid attention to at the same time:

(1)Different goods can be loaded in the same box only when they adapt to each other.

(2)Goods at the same unloading port can be mixed in one container.

(3)The stacking level and method of the goods in the container should be determined according to the size of the container and the packing size of a single piece of goods. When loading into the container, make full use of the container capacity as long as the total weight cannot exceed the maximum load allowed by the container.

(4) When different groceries are mixed in the same box, the placement position of the goods should be reasonably adjusted according to the nature, volume, weight and strength of the outer packaging.

(5) The weight of goods in the box shall be evenly distributed.

(6) When stacking the goods in the box, the stacking layers of the goods shall be determined according to the packing strength of the goods. In addition, in order to prevent the lower goods in the box from being crushed, cushion materials should be placed between the goods.

(7) Heat insulation or insulation materials shall be added between goods to avoid mutual abrasion, wetting and fouling of goods.

(8) The loading of goods should be strict and tidy, and no gaps should be left between the goods, so that the inner volume of the box can be fully utilized, and the damage caused by the collision of goods can also be prevented.

(9) Fastening measures shall be taken for goods near the door to avoid the collapse of goods.

(10)Goods with damaged packaging are not allowed to be loaded. Even minor damage should be repaired before loading into the box.

What is the container loading inspections process?

1.The inspector and the factory confirm the time and place of loading. Arrive at the loading place on time.

2.The inspector and the relevant departments of the factory shall handle the data transfer and container loading inspection procedures.

3.Upon arrival at the loading site, the inspector shall first confirm that the container is free of damage, deformation, crack, accumulated water, oil stain and peculiar smell, and that the floor inside the container is flat. There should be no different floor heights in the container.

4.Check the goods: check whether the quantity of products on site is consistent with the product details provided by customers.

5.Size and weight:

To measure the size and weight of products and cartons, they must be measured and weighed under the supervision of the person in charge of factory loading.

6.Take pictures of the products:

It is required to take the product box mark, product appearance and details. Ensure that the loaded goods are consistent with those provided by clients.

7.Loading and stowage: calculate the space occupied by the goods in the container according to the theoretical data on the loading list, and arrange the packing characteristics of the goods: arrange the ranking according to the characteristics of the factory goods, compare with the marks made in advance, and test whether they are overflowing.

8.Supervise the loading workers to place the goods correctly, arrange the space in the container reasonably, and ensure the goods are placed neatly and orderly.

9.Loading supervision:

- Confirm that the container loading inspections quantity is consistent with the actual list.

- Ensure that the outer box of the loaded goods is intact and undamaged.

- Ensure the barcode is intact.

- Do not leave the container during loading.

10.Reinforcement: The inspector shall reinforce the goods according to the characteristics of the goods in each factory, and finally arrange trapezoidal reinforcement to prevent the goods from collapsing.

11.Taking pictures:

- Take photos during loading: take photos during empty container, half container and full container.

- Photographing of containers: including license plate number, vehicle model, container number, etc.

- Take a close-up photo of the seal.

12.Report of container loading inspections.

Matters needing attention of container loading inspections?

Matters needing attention in container loading inspections.

- Get the necessary information such as container number and seal number as soon as possible.

- Confirm with the factory before departure whether the goods are all ready and ready for loading at any time.

- Arrive at the packing place in advance and check the goods to be packed.

- The inspector should control the scene throughout the whole process to avoid damage to the outer box and brutal operation by the containerizer.

- Careful consideration should be given to the porter’s suggestions in the process of container loading inspections, and the principle should not be compromised.

- In case of any unexpected situation during the process of container loading inspections, such as incomplete loading of goods and not full enough of container,contact the customer immediately, and do not ship without the customer’s confirmation.

- Check whether there are any missing or unloaded goods in the warehouse before sealing the container door.

- Information feedback: If there is any problem in the process of container loading inspections, feedback should be given in time. For example, when the total volume of the ordered products is close to the theoretical limit, and the inspector cannot ensure whether it can be loaded, it is necessary to inform the customer in advance and ask the customer to make a decision on whether to come out. Especially under the clause that partial shipment is prohibited under L/C conditions, it is particularly important.

What is the information reflected in the report?

CQI Inspection’s Comments and Summary

As an essential link before shipment, container loading inspections is very important to the transportation of goods. Through this article, we can clearly understand the container loading inspections, the inspection process at the loading site and the relevant precautions, and know that the container loading inspections is not only simple counting and monitoring the site, but also the precautions for packing involve all aspects. Therefore, it is particularly important to have a professional and experienced inspector in the process of container loading inspections, which can control the risks macroscopically and ensure the safe and complete arrival of the shipped goods at the destination.

At the same time, through the comparison of different scale inspection companies, we can know that price and brand are not the main factors that determine the quality of a company, but we need to know whether this inspection company can analyze from the customer’s own characteristics and put itself in the customer’s perspective. Only with such a service concepts , it can be a reliable inspection company for importer.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.