Disposable tableware is mainly made of paper, pulp, polyethylene terephthalate, polyethylene, biodegradable CPLA, PLA and talcum powder, etc., including disposable plates, disposable bowls, disposable cups and disposable silverware.

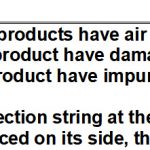

Disposable Tableware Bad Reviews-Industrial Distribution

The main applications of disposable tableware are domestic and commercial use. Commercial use dominates the terminal market, accounting for 79.6% of the market share.

In the next few years, the Asia-Pacific region will occupy more market share, especially in China and the fast-growing Indian and Southeast Asian regions.

Disposable tableware industry is widely distributed in China, but its main producing areas are in South China, East China, Southwest China and Northwest China of China.

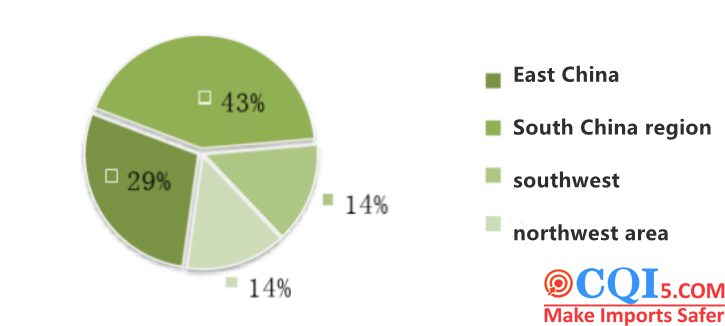

Disposable Tableware Bad Reviews-E-commerce Statistics

Through investigation, this paper extracted the hot products of disposable tableware category from two major e-commerce platforms in China and Amazon USA Station for product analysis, and collected the Disposable Tableware Bad Reviews for analysis. The analysis results are as follows:

Disposable Tableware Bad Reviews-Example Analysis

Disposable Tableware Bad Reviews-Plastic tableware

Disposable Tableware Bad Reviews-Packaging problem

There is unknown black stain on the edge of the plastic box.

Disposable tableware is generally made of raw materials such as plastic or pulp, and the internal and external packaging of qualified products must be complete and sealed tightly. Therefore, the external packaging of CQI must pass the box drop test during inspection, and at the same time, it is necessary to check whether the internal and external packaging has obvious damage and pollution.

Disposable Tableware Bad Reviews-defective workmanship

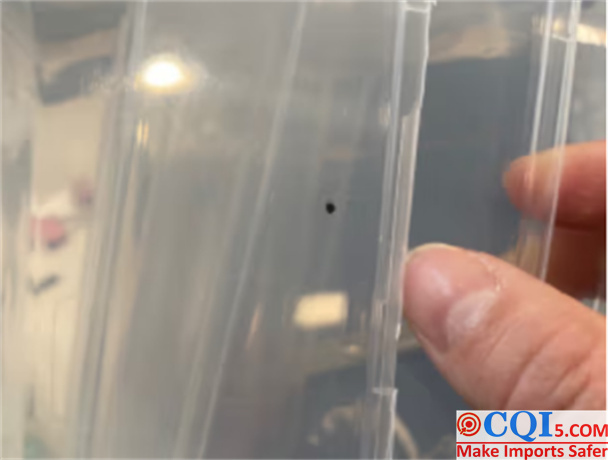

When the outer packaging of the product is good and there is no obvious extrusion, the product is still damaged and cracked. The main reason is that the product itself has certain quality problems.

The reasons for its existence may be:

1. Poor quality of raw materials and too many impurities.

2. Poor processing technology of disposable tableware leads to too long heating time.

3. Or use plastics that have been recycled too many times.

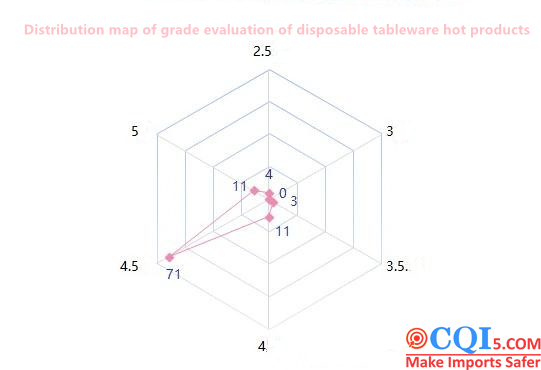

As shown in the figure, there is a set of glue similar to dry glue in the box, all of which are available.

There are a lot of plastic wires in it. Pay attention to hygiene and buy carefully.

When there are obvious injection marks on the bottom of plastic tableware and plastic wires inside, it is usually due to processing technology problems, such as low nozzle temperature, cold material residue, large pressure loss and cold material marks or stress marks on the product surface. Too high, easy to overflow, showing radioactive white marks and wiredrawing.

There are black spots in plastic injection products (inside), which may be caused by various reasons, such as impure granulation, when raw materials are processed, and the raw materials are not clean. Impurities and foreign substances are mixed in the feeding process; The raw material is impure, and the low melting point material is mixed with the high melting point material particles.

Most of them are due to the product design problems of the manufacturers, resulting in the size mismatch after molding; A few of them may be illegal sellers who mix different batches of products for secondary sale.

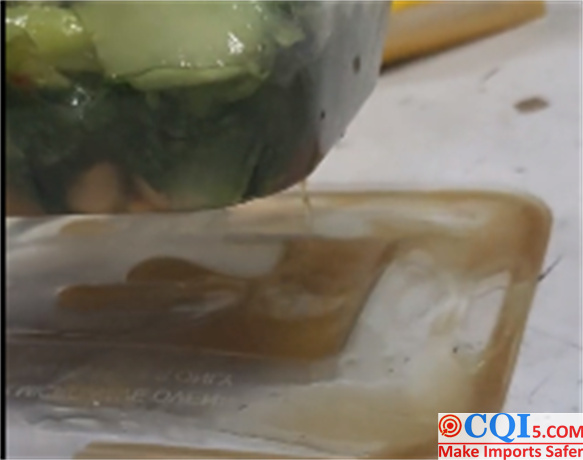

It’s not good at all. It’s filled with food, and the soup will flow out.

1. The tightness of the product itself is poor.

2. Enterprises use a large number of prohibited materials such as calcium carbonate, talcum powder, industrial paraffin and waste plastics in production, which leads to the mutual dissolution of minerals and additives in lunch boxes with water, vinegar and oil contained in food, so there will be oil leakage, water seepage, deformation and sticking of rice.

Disposable Tableware Bad Reviews-False information

This kind of situation is mostly caused by false propaganda by manufacturers. In order to save raw materials and reduce costs, manufacturers will exaggerate propaganda and increase sales, which will lead to the wrong goods. CQI inspectors usually measure the size and capacity of each product in detail based on the list provided by customers, and any inconsistencies will be truly fed back to customers.

Usually, the fake environmentally friendly plastic lunch box is soft to the touch, and when it is gently torn, it will burst, and when it smells pungent, it will choke your eyes, and it will easily leak when it is deformed by heat.

Note: Plastic disposable tableware is usually prone to other defects in appearance, such as rough edges, burrs, crystal spots, bubbles, mold defects, burrs and swelling.

Disposable Tableware Bad Reviews-Degradable tableware

Degradable tableware is generally paper products (including pulp molding, cardboard coating), edible powder molding, plant fiber molding, etc. Different tableware has different fiber proportion according to the shape, angle, hardness and rigidity of the product. Of course, plant fibers such as straw, straw and reed will also be added as needed.

Paper disposable tableware, with low overall strength, is easily deformed and damaged by external forces. Therefore, thickened cartons must be used on the outer packaging and stacked orderly.

When insects or other living bodies appear in the interior of such products, it means that the storage place of the goods has been polluted in a large area, and due to the imprecise inner packaging, the pollutants enter, resulting in serious quality and safety problems, which should never happen.

CQI inspectors usually need to strictly check the storage conditions of products during inspection, so as to avoid contamination of products due to long-term storage or transportation.

This kind of situation is not uncommon. For details, please refer to our previous article: Game chair moldy quality accidents.

Usually, the inside of disposable paper cups has a moisture-proof layer, which can protect the main material from wetting/leaking like oil paper coated with tung oil or other drying oil. However, when the paper cups are found to leak easily in normal use, the reasons may be as follows: 1. Cracking at the bonding place of the paper cup wall and bottom; 2. The moisture-proof layer is uneven, and there is no oil layer penetration.

All these are caused by poor technology, which are serious product quality problems.

In the production process of pulp tableware, cooling, setting and drying directly affect the product quality. When there are many scraps of paper in pulp tableware, it may be because the materials and additives of pulp are poor. During cooling and setting, the fibers of the product are stretched and the binding force between fibers is destroyed. Improper drying method leads to structural damage.

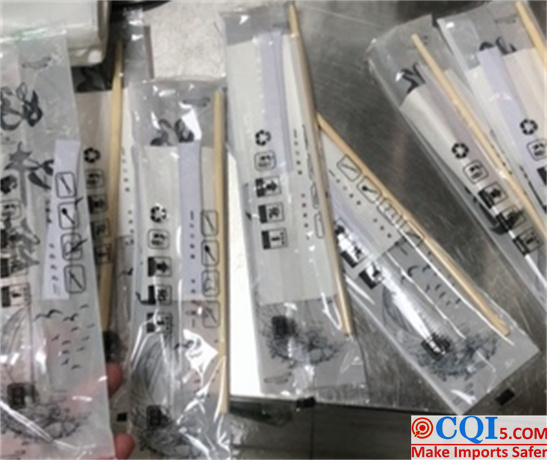

The shelf life of bamboo and wood tableware is relatively short, usually only 4-6 months, while poor quality raw materials, poor packaging and improper transportation and storage conditions will accelerate the mildew of bamboo and wood tableware.

This kind of tableware may be bent and deformed after being wet, and even spots other than bamboo or wood, such as small black spots, may appear.

Therefore, the moisture content of such products must be tested (wood: 7%-15%, bamboo ≤10%), and CQI is usually tested in multiple groups to ensure the reliability of the data. Once it exceeds the limited value, it will be a serious quality problem.

This kind of situation is mostly caused by poor debugging and quality control of factory machines.

Traditional chopsticks are a pair. When consumers receive a chopstick, it is very easy to have customer complaints, which is also very concerned by all catering industries. Therefore, testing the integrity and matching of products is also one of the key items that CQI pays attention to in the inspection.

Note: Bamboo and wooden tableware also has surface fiber cracking, defects and burrs; Color change; Odor; Clip skin; Insect pests and other appearance defects.

Disposable Tableware Bad Reviews-Aluminum foil lunch box

The characteristic of aluminum foil lunch boxes is that they are soft and can change their shapes at will, and at the same time, they can easily be squeezed during transportation to destroy the original shape. Therefore, standardized and complete packaging is indispensable.

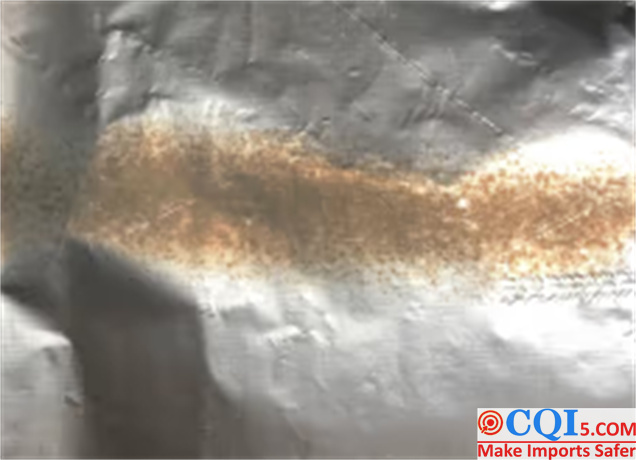

This is because the surface is rusted, or aluminum oxide is produced, which is foamy powder.

Actually, the reason for this is that unqualified stamping oil is used in the stamping process, or this process is not used, that is, the products are not subjected to rust prevention and corrosion prevention in the production process, which leads to oxidation and rust of the products.

Disposable Tableware Bad Reviews-Analysis And Summary

Based on the above product defects, the Disposable tableware bad reviews of reason can be divided into three categories:

Disposable Tableware Bad Reviews-Illegal Raw Materials

The enterprise uses unqualified or inferior raw materials, which may contain a variety of harmful substances, and there is a big problem in health and safety. Some disposable tableware will add a lot of industrial calcium carbonate, recycled waste and industrial paraffin in the production process, and these residues will have a huge impact on human health, while most products using illegal raw materials will show abnormal color and obvious odor.

Disposable Tableware Bad Reviews-Processing Technology

due to the simplification of technology, the nonstandard operation and the aging of processing equipment, all kinds of problems will appear after the products leave the factory, such as poor performance, unqualified load, large volume deviation, leakage and other problems, which are the most important problems at present.

Disposable Tableware Bad Reviews-Packaging And Storage

The packaging of disposable tableware should be good and undamaged, the box should be clearly marked, and it should be stored in a dry and ventilated place to avoid mosquitoes and be sterilized regularly. Unqualified places usually lead to damp and mildew of products, damage to the internal structure of products and other pollution.

Disposable Tableware Bad Reviews-Non-Conforming Degradable Materials

for example, some enterprises use calcium carbonate-filled products as degradation products, but in fact, such products can’t really degrade.

So do you have a basic understanding of the common defects of disposable tableware? Please feel free to comment and add any questions. You can also go to our official website to check more relevant information. CQI will take you to know more about the industry!

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.

C