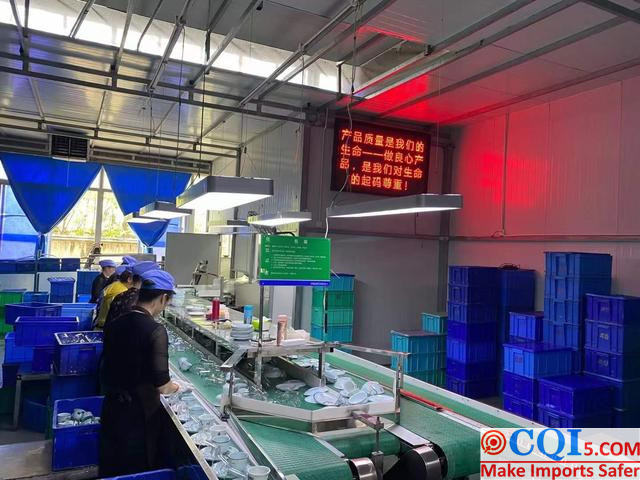

What Is The Disposable Tableware Production Process?

How to judge the quality of disposable plastic tableware well, we should not only know what are the bad reviews of disposable tableware? At the same time, we should also understand their production technology. Only in this way can we get twice the result with half the effort in the inspection.

The production technology of disposable tableware (except bamboo and wood) is that fiber-containing plants are used as raw materials, crushed, beaten, and then added with water-proof and oil-proof additives to make slurry, which is injected into the mold by a water pump through a pipeline, vacuumed and sucked into a blank, and then shaped at high temperature and high pressure, trimmed, disinfected and packaged.

Disposable molded tableware is made by using plastic or plant fiber slurry with a set concentration, passing through a disposable tableware mold with a large number of meshes, making plant fibers uniformly deposited on the mold through a certain form of adsorption pressure, and then dehydrating, drying, demoulding and subsequent deep processing. The specific process is as follows:

Disposable Tableware Production Process Of Pulping

In order to improve the strength and other properties of disposable tableware, the main raw materials and chemical auxiliary materials in the materials should be prepared first, and mixed with materials with a certain beating degree and a certain concentration to form disposable molding raw material slurry.

Among them, the role of crushing and disk grinding is to saponify the fibers to improve the binding capacity of the fibers. Chemical auxiliary materials are added to improve the humidity resistance of the mold and the waterproof performance of the finished product. Specific chemical auxiliary materials can be added to prepare the slurry. Finally, water is added to adjust the concentration of the puree to about 2%, so that the puree can be dehydrated and molded on the disposable tableware mold.

Disposable Tableware Production Process Of Molding

Molding is the blank of semi-wet tableware made from puree. That is, the material after pulping process is dehydrated on the metal mesh mold to form a wet mold. This is the key process in the production of disposable tableware. About 95% of the water in the material is removed during molding. Therefore, this process plays a decisive role in product quality, material and energy consumption, production efficiency improvement and breakage rate. The molding quality depends on the molding method, the structure of molding machine and die, and the quality and puree quality.

Disposable Tableware Production Process Of Squeezing And Drying

The process of squeezing out the water that has not been removed from the mold during the molding process with a special press to reduce the cost of drying and dehydration is called squeezing. At the same time, compaction can improve the adhesion between fibers and increase the strength of tableware.

Drying is the process of heating and evaporating disposable tableware molds by using the heat in drying channels or drying ovens to remove the residual moisture after molding and pressing, and at the same time, to sterilize them. As the heat energy consumption in the drying process is large, the cost consumed is about 300 times that of molding dehydration, so the whole drying process should be designed reasonably to save investment. In addition, in the drying process, in order to improve the oil resistance, water resistance and high temperature resistance of tableware, food glue can be coated on its surface to form a film. Among them, the inner impermeable layer can be made of all natural sugar and protein materials.

Disposable Tableware Production Process Of Integer and Trimming

In this process, the disposable tableware mold is heated for pressure setting, calendering, and eliminating the net marks left after forming, so that the inner and outer surfaces are flat and smooth. Some characters and patterns can be pressed according to different customers’ and usage requirements, and at the same time, the burrs on the edges of tableware can be removed.

Do you have a preliminary understanding of the production technology of disposable tableware now? Do you know how to judge the quality of disposable tableware? -What inspections will these products do before they leave the factory? For more information, please refer to the inspection standard of sexual tableware.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.