What details will you learn from packaging quality control?

The kitchen electronic scale has a fashionable and unique small shape and is used as a tool for accurately measuring the weight of food raw materials during cooking. Especially for consumers who like cooking, the electronic scale inspection has to be done, with emphasis on checking whether its weighing is accurate. For importers, weighing tests are also their most important concern. Today, the one chosen to be introduced. The surface tray is specially made of stainless steel. The maximum limit of weighing is 3 kg, which can better meet the needs of consumers for cooking materials. The product is powered by two AAA batteries, effectively prolonging the standby time.

The electronic scale inspection mainly checks whether the product meets the consumer’s requirements from the aspects of product packaging, appearance, size and basic functions, but also helps importers to realize how to select electronic scales without being deceived by the factory.

The first step of packaging quality control is to open the carton

The packing is simple, a white box. The front of the box is marked with the biggest feature of this electronic scale: the maximum weighing is 3 kg and the division value is 0.1g.

The main information on the back of the box is the product model, maximum weighing, division value, stress sensor and volume conversion, as well as the tips for setting zero and removing skin, high-quality stainless steel and using two AAA batteries in addition to the four characteristics.

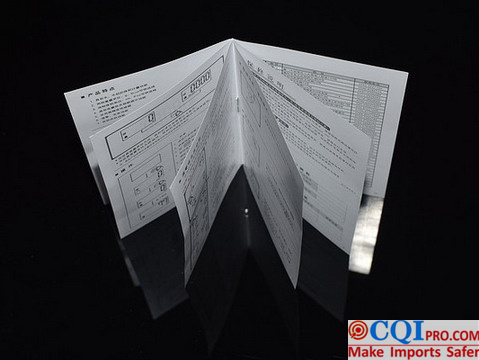

There is one electronic scale and one instruction ( with product quality warranty card ) in the packing box.

The instructions are carefully written and the related operations are also described in detail. Plus warranty card, the warranty period of the product is 1 year, and the address and contact number of each after-sales service outlet are available.

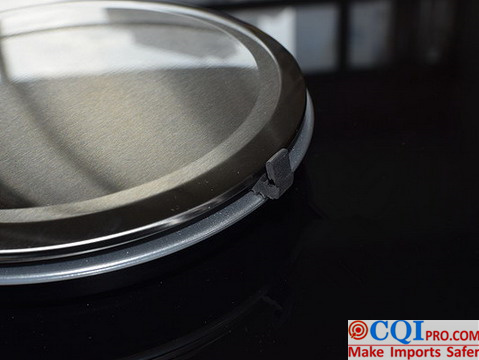

When the products are packed out of the factory, shockproof rubber strips are lined on the front and back of the weighing plate to prevent the weighing plate from being extruded and deformed during transportation,which will affect the accuracy. Therefore, importers should also check the accuracy again when receiving products to avoid consumer complaints.

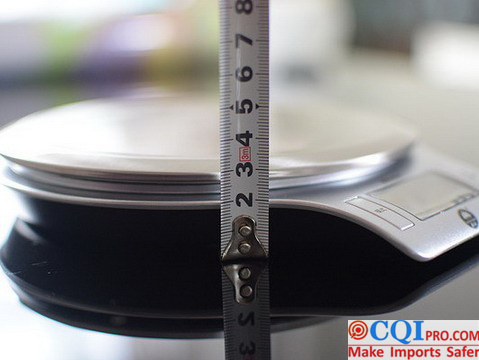

The weighing pan of the electronic scale has a diameter of 17cm, a maximum length of less than 21 cm, a thickness of 3 cm, and an overall weight of about 400 g, which is small and light.

The electronic scale has six anti-skid rubber pads on the back, so although the product is light, it is placed on a smooth surface and has good adsorption, so there is no need to worry about unstable placement.A unit adjustment button is designed on the back of the corresponding electronic screen to switch between ounces and grams.

This electronic scale has a special design and uses two AAA batteries.Most of the electronic scales are used in button cell. Button cell has higher replacement cost and smaller battery capacity, so the experience is not very good.

The second step of packaging quality control is weighing test

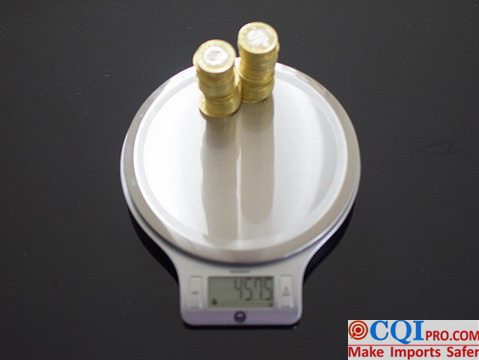

Since it is used for weighing, the most important thing is to see if the weighing is accurate, and it is also the most important link in the electronic scale inspection. The evaluator has no weight in his home, so he can only find a currency with a better standard.

Chinese orchid stainless steel dime. The nominal weight of the bank is 3.2g and the weight measurement shows 3.3g.

Commemorative coins to commemorate China’s war of resistance. The nickel-clad steel commemorative coin was weighed 5.981 g by someone on the network using an analytical balance, and the measurement showed 6.0g.

The bank ordered silver coins. The nominal weight is 50g and the measurement shows 49.7 g.

For larger weights, combined weighing has also been carried out, and the error between the weight measurement and the nominal weight is basically within the nominal dividing value range, so the nominal weight display is still more accurate and worth affirming.

In addition, the evaluator also tested the influence of the different placement on weighing, as shown in the following figure. It can be seen that only in the case of extreme deflection,the weighing will show obvious deviation, but the deviation is only 0.5g and is also within the range of division values.

The last step of packaging quality control is each mode test

For electronic scales, unit switching, peeling and weighing are all basic functions. Even if the electronic scale bought by the importer does not have the peeling function, it can be peeled and weighed by the weight-bearing zeroing button. The focus of this electronic scale inspection is to check the conversion between weight and volume.

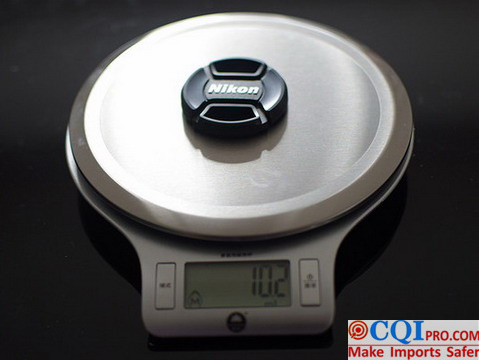

Take the lens cover as an example, the weighing display of the lens cover is 10.5 g.

Switch to the water volume measurement mode through the mode key, and the displayed volume is 10.5 ml, with a built-in default density of 1g / ml.

Switch to the milk volume measurement mode through the mode key, and the displayed volume is 10.2 ml, and the default density is 1.029 g / ml. This is consistent with the common sense setting of the density of 1.0288 g / ml of ordinary milk.

It is worth mentioning that this electronic scale also has the function of automatic shutdown ( without any operation within 2 minutes ), or can be manually shut down by pressing the zero key for a long time. At the same time, it has the functions of low power prompt, overweight error reporting, screen prompt after mode switching and so on. These additional functions obviously increase the convenience of use. Importers should choose such a multifunctional electronic scale in order to be more in line with the consumer market.

Overall evaluation of packaging quality control

For this low-price kitchen electronic scale, after electronic scale inspection, it is found that the main advantages are: accurate weighing and no false division value; AAA battery design;simplified mechanical button design;display prompt, etc. The main disadvantages are: the design of product appearance is not very beautiful;the range can be larger;the weighing pan is made of brushed stainless steel, so it is easy to collect fingerprints.It would be better if it were made into a matte surface.

Through the demonstration of electronic scale inspection, I believe importers can fully understand the relevant tests of electronic scales and have more confidence in the products. Of course, there are all kinds of products tested by CQI. The electronic scale is only one of the representatives of small household appliances. Test range describes the product range of CQI inspection in detail.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.