Feeding bottle brush inspection helps importers check qualities

Infants and young children are a special group. The quality standard of their products is higher than that of adults, and feeding bottle brush inspection is stricter. Importers should first understand the needs of the target market when choosing suitable baby products, such as the bottle brush described in this article. Many mothers only care about the cleaning and safety of the bottle and do not think it is necessary to buy high-standard brushes. But if the bottle is not cleaned sufficiently for a long time, fat will adhere to the bottle wall and white granular substances will appear. Over a long period of time, these substances will deteriorate and the bottle needs to be renewed. At this time, importers should seize the opportunity to publicize the safe and clean bottle brush and emphasize the selection of a good bottle brush, which plays a vital role in the maintenance and service life of the bottle.

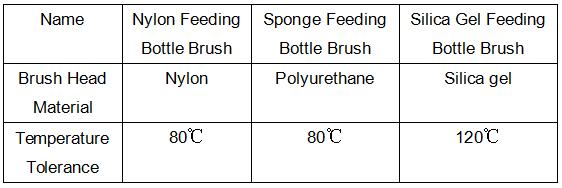

Ordinary brushes cannot withstand high-temperature disinfection, and only special bottle brushes can withstand it. Before leaving the factory, feeding bottle brush inspection or Lab testing, importers should pay attention to this point, although there are three main materials for bottle brushes in the market: nylon, silica gel and sponge. But can these materials meet the standard of high temperature disinfection?

In order to ensure the uniformity of product quality, CQI chose the same manufacturer’s products, but included three different materials. Help importers analyze the advantages and disadvantages of different bottle brushes, and solve the learning of brushes.

Feeding bottle brush inspection shows the security of the product

1.Whether the material selection of the product is safe and high temperature resistant

The brush heads of nylon and sponge can not be sterilized by high temperature, so the safety is relatively low. The silica gel brush head can be sterilized by boiling in water at high temperature, and it is inherently antibacterial and does not contain bisphenol propane ( BPA ), which is slightly better in safety.

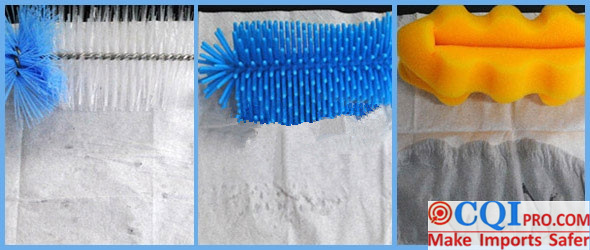

2.Whether the product will drop hair and debris to create potential safety hazard

The bristles of nylon and silicone bottle brushes did not drop or break after pulling hard. After rubbing the sponge brush head violently and slapping it on white paper, no sponge crumbs were seen to fall.

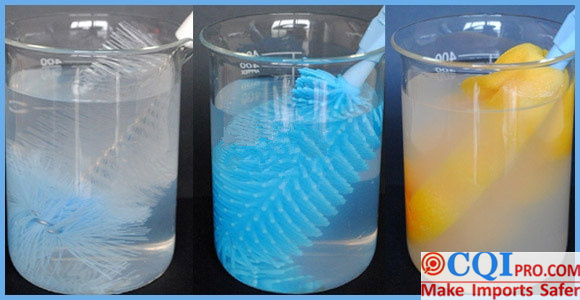

3.Whether the product is easy to dry after being placed,it will breed bacteria

The bottle brush made of nylon and silica gel did not show any obvious water stain residue in the test. In contrast, the strong water absorption of sponge can be seen from the soaked paper towel, so the sponge bottle brush is more likely to breed bacteria when placed.

Cleaning Effect

Fit with bottle

Nylon silk is soft and has good adhesion, but it is difficult to clean the bottom edge and shoulder of the bottle. When the silicone bottle brush is used, it cannot reach the bottom edge of the bottle. Sponge bottle brush is soft and has strong adhesion. Bottle shoulders at the bottom of the bottle can be cleaned easily and the adhesion is the best.

Portability and durability

1.Evaluation of durability and abrasion

During the test, we can see that nylon material is hard and causes the most wear, while silica gel and sponge have no obvious damage. In addition, the metal brush head bracket has strong flexibility and may be deformed when used for a long time. However, the sponge brush head is more likely to be damaged and deformed after a long period of use due to the nature of the sponge material.

2.Easy cleaning degree of brush head

Nylon and silica gel show similar effects and can be cleaned with little effort. The sponge brush head still has turbid water due to its strong water absorption, which once again shows its disadvantage in cleaning.

So for professional importers, baby bottle brushes frequently used by infants are not only the choice of appearance, but also the pursuit of different effects for brushes made of different materials. After feeding bottle brush inspection, importers can clearly see that all performances of nylon bottle brushes are in a moderate position and have balanced performance. Silicone bottle brushes have outstanding performance in terms of safety and durability, and are more recommended for purchase. The cleaning power of the sponge bottle brush should not be underestimated. It is more suitable for consumers pursuing cleaning effect, but its durability is relatively poor and its replacement frequency is higher.

In the infant market, importers should not only grasp the consumption standards of consumers, but also choose high-quality products. Find a region with a strong production chain in China and arrange feeding bottle brush inspection to avoid missing out on the high-profit market.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.