The Actual Cause of The Game Chair Quality Accidents

Today, I would like to share an eight-month “unsolved” case, namely game chair quality accidents, Please learn the background and read with questions.

Known as the “home of the chair industry,” Anji,Zhejiang,is the world’s largest office chair manufacturing base, the county has a total of more than 700 chair production enterprises. Usually, for every 3 chairs produced worldwide, 2 of them are from Anji. So one of our e-commerce clients from Mexico has chosen a gaming chair factory with some strength in Anji. For the client, as an expert in electronic products, it was time for them to choose a gaming chair as a breakthrough point.

In May 2021, when I was communicating with the salesperson about the inspection requirements, she revealed some very interesting information:

1. The client’s cost of this chair is very low, which is the cheapest chair in the industry. Our own factory only makes high-end chairs, so this one is outsourced.

2. The product is not able to do bare drop test, only the wheels.

3. The salesperson said she had no confidence in our inspection, because she could not meet the requirements of several tests.

To be honest, this is the first time I met such a frank salesperson. So I also gave feedback to the client one by one about the tests that the factory could not achieve and the client said it was acceptable. So after the first inspection, the goods were sold out smoothly. The client was happy to place a second order and doubled the quantity.

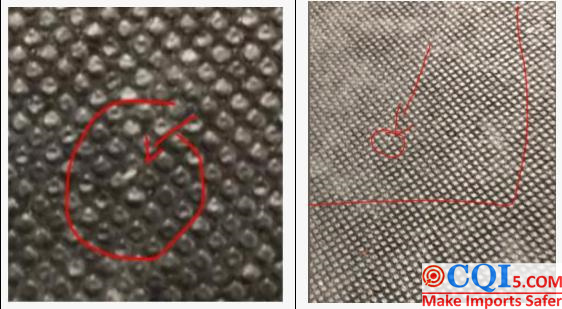

But more than one month later, when the second shipment arrived at the client’s warehouse, they discovered a major problem: 90% of the product has arrived completely damaged and contaminated by fungus and insects. But the product packaging was not damaged and there was no water damage. So at this moment, the client needed our assistance to re-investigate the situation on the day of inspection in order to discover the cause of game chair moldy quality accidents.

Moldy condition on the back of chair in game chair quality accidents.

The following information and analysis are obtained from various aspects:

Factory:

1. They have been in the furniture industry for more than 20 years and have never encountered such problems. This shows that the factory’s quality control department can easily ignore such problems.

2. The raw material of the product is exactly the same as the first order and it is produced by the same factory.

3. Other clients’ products also use the same batch of raw materials and the same style, without problems.

4. The same batch of goods were exported to Brazil at the same time.Later,we learned that the Brazilian client did not receive any consumer complaints.

5. The raw materials are not mold-resistant and do not do mold treatment.

6. This product belongs to the low-end goods, the factory will not keep the sample.

7. The goods finished producing in August,but CQI went to the factory for inspection on September.9th.

CQI:

1. The cushions and backrests of the chairs are made of construction board (secondary use plywood), which are normally very dry and will not be tested for humidity. However, during the inspection, we tested the humidity to ensure better quality control.

2. On the day of inspection, 50% of the goods were not finished production. Because the goods were stored in the factory for two weeks after our inspection before shipping, the preservation of the goods during this period was under suspicion.

3. From August to September, Anji has been in the rainy season. If some of the products are damp before shipment, then in the closed environment of the container, goods were with the poor air flow, coupled with the high temperature, the mold reproduction speed would be accelerated, it will spread to the whole product.

4. The problem of mold often occurs in furniture inspection, basically because the material does not have the characteristics of anti-mold and anti-bacteria as well as improper storage. So anti-mold materials and treatment are the key.

Finally, after several days of research and confirmation from various aspects, there was a 90% chance that the leather and wood were damp which caused the game chair quality accidents. The shipment could only be reworked locally in Mexico by fumigation. At the same time, the factory also realized their improper storage and offered to compensate more than 2000 US dollars.

Let’s go back to April,2022, the client went on to place a third order at this factory. Can it be safe and sound this time?

First of all, after I had a talk with the salesperson, I learned that they replaced the outsourcing factory this time. After we finished the inspection, we also found that the quality was indeed a little better than the previous factory. From the photos, you can also see that it is much cleaner and tidier.

To avoid what happened last time, the inspector carefully looked at the leather as well as the interior of the product and tested the humidity of the products. But unfortunately, this time, not only the missing accessories and packaging, but also the internal sponge with dirt on it. More importantly, the humidity of the wood was as high as 18%! After this operation, the client’s QA department immediately contacted CQI and asked for a re-inspection after the factory reworked the product.

Before the re-inspection, the factory physically treated the entire shipment, which means sunlight. So the humidity level was reduced to 12% at the second time.Normally, the industry’s permissible range for wood humidity is 8-14%. Although the salesperson repeatedly emphasized to me that after the complaint last year, she had learned a lesson. But it is not only to change the outsourcing factory so simple, the choice of raw materials is crucial! Since there is no guarantee of what will happen in the subsequent transportation in the early stage, is it necessary to reduce the risk first in the controllable link?

CQI’s case analysis

The reason why game chair quality accidents is “unsolved” is not only because of the long time, but also because it is a “strange case”. Professionals have said that they have never encountered in decades of practice,although the construction board is low-cost, the risk of multiple use is also small. In addition to the preliminary link, I wonder if you have thought about the transport problem. Some time ago, a colleague responsible for loading containers told me that the containers shipped to Mexico were found to be wet in large quantities. It can be seen that the pre-shipment inspection plus loading inspection are the double protection. If I were an importer, I would not skimp on one of them.After all, catching up with the sales period of next quarter is my ultimate goal.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.