Surprise! The Global Supply Chain Crisis Shows Signs Of Easing.

The supply chain crisis that has plagued the global economy in 2021 has recently shown some signs of easing. on Nov. 22, global freight prices have fallen over the past two weeks, port congestion has eased slightly, and many factories in Southeast Asia have resumed operations as the outbreak eases.

Lowering Freight Rates Relieves Global Supply Chain Crisis?

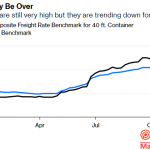

Global maritime shipping prices, while still more than six times what they were before the outbreak, have fallen from their peak in September this year. The price of shipping a container from East Asia to the U.S. West Coast fell by more than 20 percent from $18,730 to $14,885 between Nov. 5 and 12, and then slightly to $14,185 the following week. Price indices for the combined global shipping routes also fell for the second consecutive week.

Congestion at key ports is also at least no longer deteriorating rapidly, and in some cases has eased slightly. On November 19, there were 71 cargo ships waiting to unload at the two major ports of Los Angeles and Long Beach on the U.S. West Coast, down from a record 86 ships three days earlier.

The cargo and retail industries expect the backlog of ships at U.S. ports to be cleared by early 2022, and port congestion to end. By then, the U.S. holiday shopping season, which began at the end of this year, will be over, and many factories in Asia will shut down during the ensuing Lunar New Year, which is expected to reduce the pressure on freight from both the supply and demand sides and buy time to end port congestion.

Global Supply Chain Crisis Affects Global Production.

In addition, with the recent easing of the epidemic in several regions around the world, previously disrupted industrial production has gradually resumed, contributing to the easing of the supply chain crisis. since September, confirmed cases in North America, South America, Asia and Africa have been on the decline, except for the rapid deterioration of the epidemic in Europe. This has allowed the impact of the Delta strain on the supply chain to partially subside this summer.

The Delta strain began sweeping through Southeast Asia in July of this year, leading to a number of Southeast Asian countries, including Vietnam and Thailand, taking embargo measures to contain the spread of the outbreak and many factories shutting down as a result. The supply chain crisis at the time was exacerbated by the fact that Southeast Asia is one of the global manufacturing centers, especially upstream of the supply chain, which is highly dependent on Southeast Asia for products such as chips.

And now, the wave of the outbreak triggered by the Delta strain is at least substantially alleviated, if not completely receding, in countries such as Thailand, Malaysia, Indonesia and the Philippines. With the resumption of factories in Southeast Asia, the associated supply chain problems are no longer as severe as they were in previous months.

Data released last week in the U.S. alone suggest that the easing of the supply chain crisis has trickled down to the U.S. Data released on Nov. 16 showed that U.S. manufacturing output rose 1.2 percent in October, reaching its highest level since March 2019. Among them, automobiles and their parts contributed the most to the rise in manufacturing output. This suggests that the auto manufacturing industry, which was most severely affected by the previous chipsupply crisis, also got a breather.

The U.S. retail industry also prepared in advance during the supply chain crisis, some began importing goods earlier than in previous years, and some directly rented their own ships to ship goods to avoid shortages of goods during the shopping season. Currently, Wal-Mart, Home Depot, Target and other major retailers are saying they are well stocked for this year’s holiday shopping season.

The survey shows that almost all experts believe that the supply chain crisis has either peaked or will peak in the fourth quarter of this year.

Global Supply Chain Crisis Still Exists.

However, the epidemic situation is still the biggest variable in the supply chain crisis. Since the recent supply chain crisis can be alleviated by the receding epidemic, the future may also be aggravated by the epidemic and the resurgence.

Europe is currently the “epicenter” of the global epidemic, having been the only region in the world to see an increase in confirmed cases for several weeks. Since mid-September, the average daily number of confirmed cases in Europe has nearly tripled. Many European countries have tightened precautions, restricted the movement of unvaccinated people, and in some cases, imposed “lockdowns.

In Vietnam, one of Asia’s manufacturing hubs, the outbreak also began to rebound in late October. Previously, the average daily number of confirmed cases in Vietnam had dropped from a peak of more than 13,000 in early September to more than 3,000 in late October. However, the epidemic in Vietnam has since worsened again, with the daily average of confirmed cases approaching the 10,000 mark, and the trend is continuing to rise. If the rebound of the epidemic in Vietnam leads to a new round of blockade measures and even spreads to other countries in Southeast Asia, it will be difficult to alleviate the global supply chain crisis.

The supply chain crisis has eased recently, but it is still far from returning to normal. Freight prices from East Asia to the U.S. West Coast are still several times higher than they were before the outbreak. And while congestion at the U.S. ports of Los Angeles and Long Beach has eased, it was almost never congested before the epidemic. In addition, in recent months, both developed countries in Europe and the United States and Southeast Asian countries such as Vietnam and Indonesia have experienced labor shortages, which may also have a lasting impact on the supply chain.

As you can see, the epidemic situation is still the baton of the supply chain and even the global economy. I am afraid that the global supply chain crisis will have to wait until the end of the COVID-19 pandemic to completely subside.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

Disclaimer:

CQI5 article information from the Internet and contributions, the copyright of which belongs to the original author, and only represents the views of the original author. This website is only responsible for sorting out, typesetting and editing the articles, reproduced for the purpose of spreading more information, does not imply that it endorses its views or proves the truthfulness, completeness and accuracy of its content, and therefore does not assume any legal responsibility.

The information contained in this article is for reference only and is not intended as direct advice for decision-making.

If we inadvertently violate your copyright, please inform us, after verification, we will immediately correct or delete the content according to the requirements of the copyright holder, thank you! Contact, email: copyright@cqipro.com

This website has the final right to interpret this statement.

Welcome to reprint, please be sure to keep information complete.