Hat Inspection Need a Clear Hat Checklist

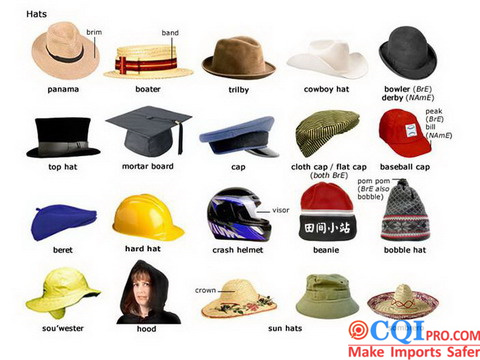

A hat, an ornament worn on the head, covers most of the entire top of the head. The hat is mainly used to protect the head, and some hats have protruding edges that can block the sunshine. Hats have the functions of sunshade, decoration, warming and protection, so there are many different kinds of products, and there are many different requirements for product selection. In the hat inspection process, different types of hats have similar test methods, but the size and style are not allowed to be wrong.

Product composition and main structure introduction

According to the detailed method, the hat can be divided into: hat top, cap roll brim, hat wall, hat brim, hat lining and hat ribbon. Simple can be divided into: hats top, hats brim and decorations.

The product core manufacturing process

Complete process: raw material preparation – cutting – sewing – printing or embroidery – sweat band – ironing setting – packaging

Among the important aspects are:

- Cutting process: The cutting personnel select fabrics, color cards, and die cutters according to the order requirements, estimate the number of times the fabrics are cut, and cut them into pieces using a press.

- Sewing process: The cut pieces will be cut into pieces according to the design, while paying attention to not skewing, wireless head.

- Sweat belt process: The sweat belt is inside the product, around the brim one, usually chooses the fabric with strong sweat absorption, and has specific needle spacing requirements, so in the hat inspection, the test of the sweat absorption function can not be avoided.

The Common Defects in Hat Inspection and the Causes

Appearance class:

- The hat is not flat, the width is inconsistent, and the top is not correct;

- The cap brim is not correct, and the rear end of the cap is obviously inconsistent from the wall spacing;

- The hatopeningand hat brim are not well shaped and have deformed folds;

- The sewing is not strong, there is open line, broken line, no return needle;

- The stitch length is not uniform, and there are problems such as jumpers, pinholes, and blockages.

Function class:

- The product is not allowed to be deformed or the color is severely degraded;

- The size is not allowed to be biased;

- No odor is allowed.

Hat Inspection - the Product Testing Parts:

Inspector field test in the hat inspection

- Appearance and cleanliness, no dirt is allowed;

- Color and printing, check whether there is color difference in batch products, or check with the sample in case of customer signing, so that customers can visually see the quality;

- The sewing effect meets the customer’s requirements;

- Abuse test: the seam, the date, the Velcro, etc., focus on checking the strength of the sewing;

- Color fastness test: Check whether the printed dry wipes on the surface will fade;

- Needle count: measure the number of stitches per inch with a ruler or tape measure;

- Product size must meet design requirements;

- Check the water absorption of the sweat band.

Because hats belong to a category of clothing, the quality requirements for sewing are the same as clothing, and even more stringent. Through the hat inspection, strengthen the production control of the factory and improve the right product quality control allows importers to see the quality of their products and improve their product design, enabling importers to break into competitors and make profits.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.