How CQI Keeps New Customers Satisfied With Their Inspection Services

The first time we “met” JZJ company was last October.

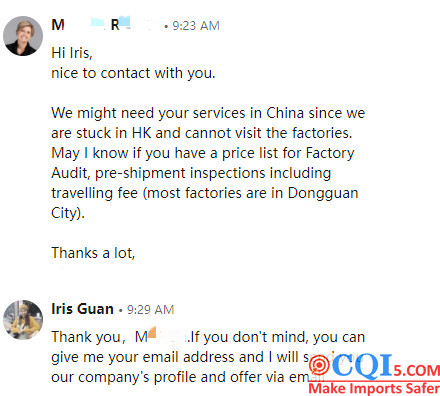

When Iris received the Linkedin message from Ms. MR “We might need your services in China ….. . May I know if you have a price list for Factory Audit, pre-shipment inspections“, she had no idea yet what kind of intersection they would have. Her LinkedIn page indicates that she is the CEO of a Hong Kong-based company that provides sourcing and supply chain services in Asia, without much more information than that.But it is clear that she is totally the CQI’s target customer.

CQI is a third party inspection company in China that focuses on quality control,ensuring import safety for importers. We are commissioned by our customers to arrange inspectors to visit the factories to check the quality of the products, write up the problems in a report and submit it to the customers. So we are kind of a part of the supply chain.

But Hong Kong people are quite shrewd, will she just go for low price regardless of the quality of service?Iris frowned. “Many Hong Kong companies’ inspectors can’t make it to mainland China in time for inspection, so this might be our chance.” That’s all Iris and her colleagues could consider.

“Whatever, let’s reply first.”

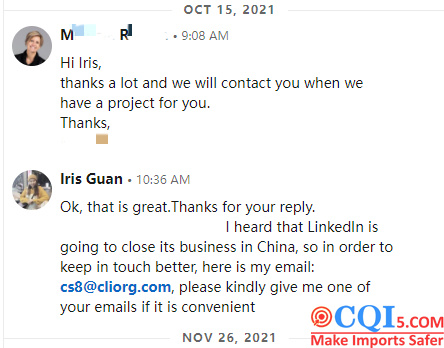

Starting from the second half of last year, Linkedin requires a VPN connection to use in mainland China. So Iris usually only opens it at work time. Afraid of missing the message, she asked Ms. MR firsthand for her email address in the reply.

After six hours, Ms. MR still did not reply, and Iris could only send her the information she needed to quote directly to her via Linkedin. Half an hour later, MR simply replied with “thanks a lot and we will contact you when we have a project for you.” Iris didn’t think much of it, looked out the window, left her email address “Iris@cliorg.com” and closed the chat window.

The day went on for a month as if nothing had happened. During this time Iris checked Linkedin messages from time to time, but all she got was disappointment.

Iris didn’t remember what the weather was like on November 26th, or what she ate that day, except that on that morning she received an email from Ms. MR , “Hi Iris, may I know if you have inspectors stationed in Shandong? We need to carry some inspections in Jining city for next week but our inspector cannot travel there. Pls let me know and thanks in advance.”

Of course we can!

With the development of the manufacturing industry and the improvement of the industrial chain in mainland China, coupled with the border with Hong Kong, Guangdong has become the most important manufacturing center in the whole of China, the economic pattern “front shop and back factory” gradually formed,Hong Kong has become the most developed foreign trade city in the world.

Among Hong Kong’s foreign trade companies, smaller companies work directly with third-party inspection companies, both to save money and professionalism can be guaranteed. Larger companies may have their own inspectors, responsible for the inspection of goods throughout China. But several inspectors have to travel throughout the country, putting all the energy on the traffic, ending up in low effectiveness .It is difficult for the QC to travel city-to-city at will because of China’s stricter policies on epidemic prevention policy.Ms. MR also mentioned in her email that their inspector cannot travel there.

Taking a deep breath, Iris decided to calm herself down first. She replied, “Yes, we can arrange the inspection, please kindly send me more details “, copying colleague Susan, one of the most knowledgeable colleagues in CQI who knows inspection like the back of her hand. Subsequent inspection arrangements and inspection requirements will be mainly handled by her with the customer.

The product list was quickly sent by MR. The product is a plush toy. The pictures below are a the product, but we have mosaic masking of the logo to protect the customer’s brand. MR told Susan that this was a complimentary accessory for the food which was DIY toy. Consumers needed to assemble it by themselves after buying it home.

This toy is small enough for one hand to hold tightly and should be a keychain decoration.

She also told us in her Product Specs for inspection:“The client always appoints XXX to do the final inspection for these goods. Then the goods are delivered to the client’s co-packer in Dongguan, who also checks them before the final packing. In the last 2 orders XXX inspection was passed with no problems but once the goods arrived at the co-packer they were found with too many defects and they were rejected (so we had to re-work them and re-test them. As you can imagine this is frustrating for all parties involved and it makes everybody loose a lot of precious time. For this reason we are now checking the production step by step, to eventually identify problems before the delivery of the goods. ”

Pre-shippment’s company was appointed by the final client instead of JZJ. They appointed a well-known international company.However, the report result of this inspection company was PASS all the time. Susan learned through Ms. MR that the final customer was an international top 500 food company. The packaging parts were produced in China, the food was produced abroad and then shipped to Guangdong, China to be packaged together. The final customer’s China office staff did the final inspections of the product. In the past two cases, this inspection was not passed, which resulted in the parts being re-shipped back to the factory for rework and the scheduled shipping date being delayed. So MR decided to cooperate with CQI to arrange the DUPRO inspection to inspect the production line and some products in advance, to rectify and rework them in advance, ensure that they can be exported smoothly.

After a few emails from Iris , the client was taken over by Susan.

Susan has been in the inspection industry for 12 years and knows CQI’s inspectors and inspections very well. If a new colleague joins the company, she is also responsible for training. If someone does not do a good job, he or she will certainly be reprimanded, so many of our company’s inspectors are also afraid of her. Only by handing over the new client to her will everyone feel assured.

From the MR’s email responses, Susan felt that she attached great importance to this inspection.She received several emails from MR after 9:00PM,so she also paid special attention to this case. Susan was aware that the first impression of the first order would determine whether the cooperation could be continued in the future.

And the customer also asked the factory to provide approved samples, which was the samples made by the factory according to the customer’s requirements before the goods were mass produced, as the perfect reference in the inspection. However, most of the customers that CQI works with do not provide them.

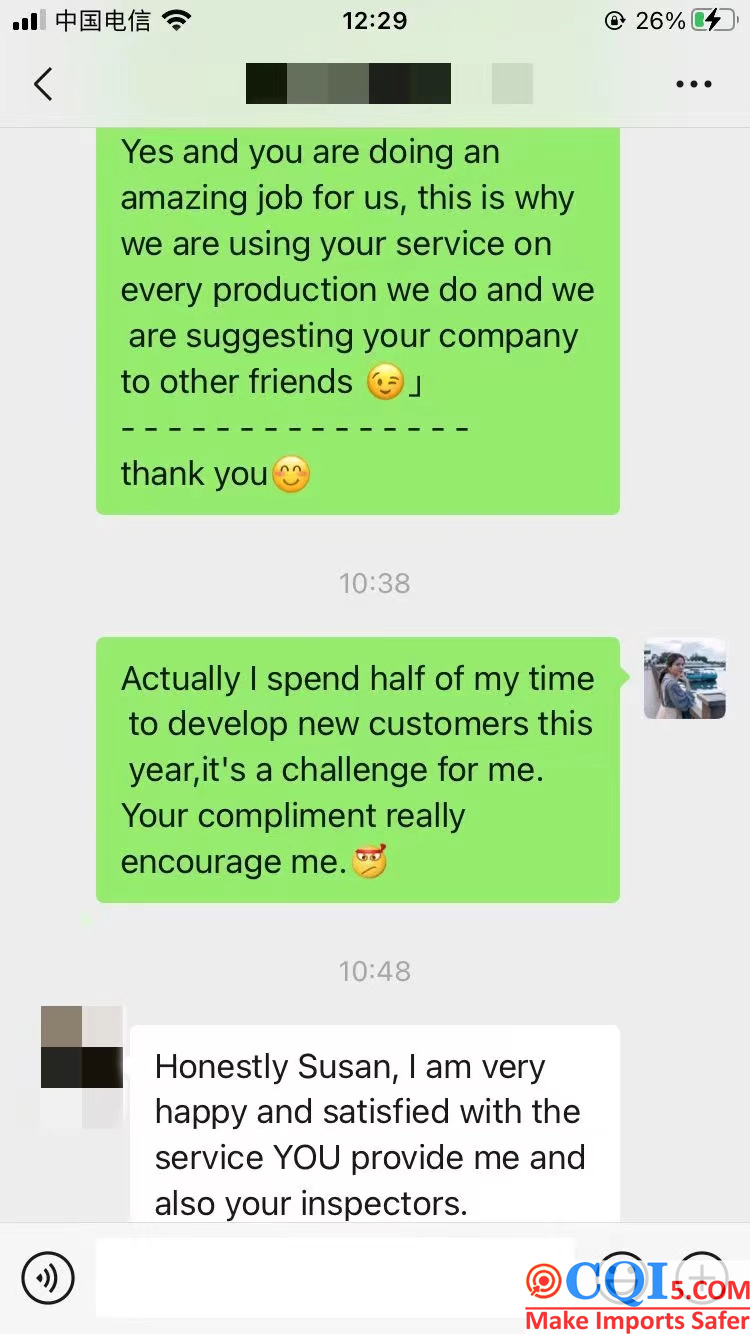

“Honestly Susan, I am very happy and satisfied with the service You provide me and also your inspectors.” This is what the MR said to Susan after 2 month.

But now everything is just beginning, Susan has not received these the praise. In the days leading up to the inspection Susan began to become anxious. In fact, she was responsible for 1/3 of CQI’s new customers. But the monthly shipments of this customer are quite large,if the first order is successful, it will bring CQI a lot of orders a year. So she didn’t dare to relax.

It was a new customer and a new product, Susan exchanged inspection points with inspectors who was good at this kind of products in advance and then prepare the inspection checklist according to the customer’s needs.

Susan took a sip of water and looked at the latest email from MR and fell into a deep thought. She had a little dilemma. The customer asked us to check the production line in the email. This is not a problem, just ask QC to take more photos of the production line details.Susan had been in the industry for many years and knows that the customer was just worried that her goods were not made in the factory but were sent out to other small workshops or factories to be manufactured.

In China, the manufacturing of various products presents a regional and aggregated distribution. For example, the main manufacturing cities of plush toys in China are Dongguan, Guangdong, Yangzhou, Jiangsu and Qingdao, Shandong.

Shandong is one of the provinces that produce the most plush toys, which means that there are tens or even hundreds of thousands of manufacturers of different sizes in Shandong. For some big factories, if the orders received recently are too many for the production line of their own factory to finish, the only way they can do is to give all or part of the orders to other factories to finish together. If these factories can’t finish again, they will continue to allocate to other factories or workshops. This is particularly risky for importers who cannot control the quality.

Just a moment ago, the factory told her that they had completed the entire quantity and there would be no more production of this batch of goods in the next few days.So we couldn’t see whether the production line was producing this customer’s products normally. In addition to checking whether the 1/2 finished product was finished as it was and whether there were any defects in the process, it was also important to check whether it was produced in their own factory.

Susan calmed down, it was not a difficult task for her. It’s just that she’s used to giving her customers the most complete service at all times and she couldn’t say things like “the factory has finished production and the production line can’t be checked” to her customers.

Susan once again dialed the factory salesman and asked if the factory had any leftover materials, including wool, accessories, etc. The factory said yes.

Susan told the client the actual situation and MR accepted us to take photos for material as a second-best solution.

The day before the inspection, she called QC again to instruct the inspection points. The inspector was too nagging her, but dared not say anything.

The inspection of the first order went fairly well, although the inspector did not find anything wrong with the customer’s request for special attention at the site, but found some other serious batch defects. For example, the pin shown below was not neat. The factory said all the products would be reworked.

Susan and MR breathed a long sigh of relief. If goods were shipped with this defect, they would have been rejected by the buyer.

But at that time Susan did not know that the inspector would go there twice …….