Newest Led Desk Lamp Inspection Standard!

1.Purpose(LED Desk Lamp Inspection Standard)

In order to clarify the inspection specifications and requirements of CQI Inspection Company for LED desk lamp , this product inspection requirement is specially written to standardize the company’s quality inspection service level for customers.

2.Scope of application(LED Desk Lamp Inspection Standard)

This inspection technical document is used to standardize the pre-shipment inspection service of LED desk lamp .

3.Defect definition for LED desk lamp inspection

Serious defects (CRT): the user’s life is a major hazard or has the potential to harm and violate the relevant safety requirements of defects

Major defects (MAJ): affect the use of the product, reduce product reliability and service life or seriously affect the product image defects

Minor defects ((MIN): the product has a slight appearance defects and does not affect the product function defects

4.The level of inspection

Sampling standards: MIL-STD-105E

Acceptance level (AQL): CR=O MA=1.5 MI=4.0

5.Common appearance and functional defects for LED desk lamp inspection

1)Shell without obvious color difference, indentation, oxidation, sand point, uneven spraying, scratches, the surface does not allow a sense of scratches / pull marks and fingerprints, no sense of scratch line diameter of not more than 0.2cm, length of not more than 50mm?The same visible surface can receive 2, different visible surface can accept 5, and scratch spacing greater than 10cm.

2)Shell no obvious bump, uneven height no different degrees of cracking, chipping edge

3)Shell without breakage, batch front, the edge of the obvious cut hand feeling, shrinkage, top white, splash, air lines and other injection shall be defective, etc.

4)Mask without obvious scratches, stains, foreign bodies, black spots, shrinkage, top white, splash, air lines and other injection defects, the surface does not allow out existing sense of scratch

5)No pulling marks and fingerprints, no scratch line diameter more than 0.15mm, length not more than 20mm, the same mask visible surface can receive 2, and the scratch spacing is more than 5cm; no loosening, rupture, indentation, skew, etc.

6)Lens without scratches, ruptures, foreign bodies, black spots, where the foreign body, black spot area shall not exceed 0.3mm

7)Reflector without obvious black spots, scratches, notches, batch front, color difference, etc., the black spot area is less than 0.5mrr2; no outgoing existing sense scratches / pull marks and fingerprints, no sense scratch line diameter not more than 0.2mm, length not more than 30mrg the same visible surface can receive 2, and scratch spacing greater than 5cm; reflector without canonical deformation

8)Screws without slippery wire, floating high, skew, leakage, specifications do not match, rust oxidation, etc., the need for salt spray test in the early stage.

9)No internal glue wire, debris, etc.

10)The body structure combination gap requirement is less than 1mm

11)The combination of the body structure is solid, no loosening or cracking of the combined parts by hand breaking

12)The font meets the requirements, the handwriting is clear

6.Common Testing Items for LED desk lamp Inspection

Tilt test

Tilt test in the most unfavorable place of the lamp body does not fall down.

Clamp light clamping force test

Clip on top of smooth glass of 10mmlf, 20N pulling force in the most unfavorable situation, no movement (based on safety regulations as the test)

Power cord pull test

25 times 20N pull on the power cord, after the first pull on the power cord to mark, the subsequent test finished power cord displacement of no more than 2mm (safety regulations as the basis for inspection)

Whole lamp temperature

Working state, the easy-to-reach parts of the lamp can not be overheated, not more than 70. C

The whole light effect

Shaking the whole lamp, the lamp body does not produce foreign body sound.

Power wire diameter

The wire diameter of internal wiring and external wiring is in accordance with safety regulations.

Lamp body shell trust test

Oil sprayed parts and painted parts must be tested for reliability (Hundred Gram Test)

Standard parts interchangeability

The parts used should comply with the corresponding standards, the same model of lamps and lanterns, the same parts should be good interchangeability, replaceable parts should have no difficulty and do not affect the safe replacement.

Overall lighting effect

No serious light leakage around the product luminous surface, and the overall no dark areas.

Labeling

There are company trademark, QCPAS Wei 100% logo, marking product model, rated power supply voltage, power supply frequency and power supply current, line power factor, rated power, or the model with which the lamp is matched.

After the test, the mark should be clearly written, and the label should not fall off and curl.

Lamp body

Product height and maximum diameter exceed the product specification requirements

Performance

No dead light, dark light, light flashing, color difference, light ringing and other phenomena when the rated voltage is lit, and the accompanying functions of the lamp work normally

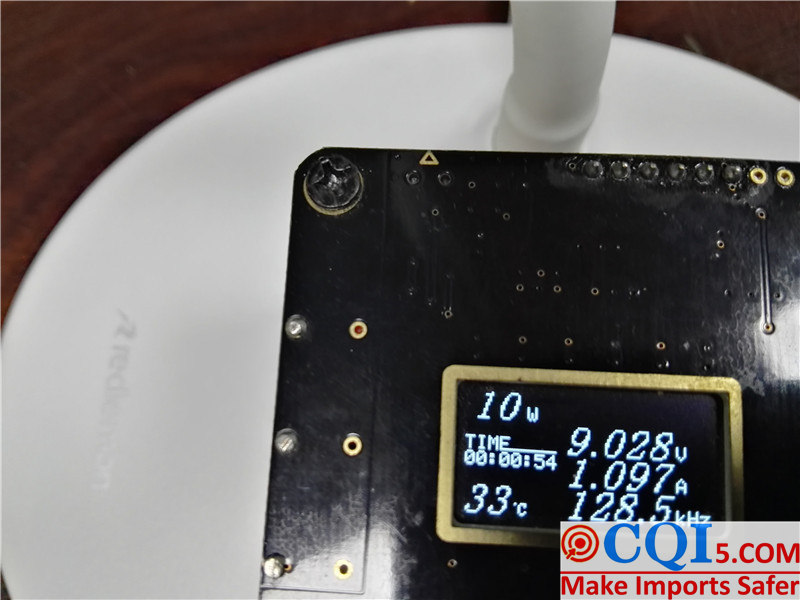

Power

Rated voltage light source, power supply power meet the requirements

Power factor

Power factor under rated voltage does not meet the requirements

Color temperature

Test color temperature at rated voltage meets the requirements

Display index

Test color rendering index under rated voltage meets the requirements

Illuminance

The illuminance of the test at rated voltage meets the requirements

EMC

Test quasi-peak, average value, the measured frequency range (0.09MHZ-30MHZ, the measured quasi-front value and level value of the data must be below the baseline, shall not exceed the average baseline 5dB.

Harmonics

Electronic ballasts with low power factor less than 25W only consider the 3rd and 5th harmonics, of which the 3rd harmonic requires < 86, the 5th harmonic requires < 61 Electronic ballasts with greater than 25W harmonics require consideration of the 3rd, 5th, 7th, 9th, 11-39 odd harmonics, of which the 3rd harmonic requires < 30 into the 5th harmonic requires < 10, the 7th harmonic requires < 7, the 9th harmonic requires < 5, the 11-39 odd harmonics requires < 3

Durability test

115% of rated voltage at room temperature for 168 hours; b. 85% of rated voltage at room temperature for 168 hours; after the test, can work normally for 15min (this item is used as a confirmation test, once every six months for sampling, regular inspection does not do this test)

Protection grade

IP20

Humidity test

Humidity test in the humidity box first, the air temperature is 20-30 C, the temperature change during the test is Shi 1 C, humidity is 91%-95% test time of 48 hours, the test time to remove, and immediately the next step of insulation resistance test and voltage test. Intermediate test

Whether the light body is normally lit, if with touch switch, check whether it is not malfunctioning. (This item as a confirmation test, the regular test does not do this test)

Electrical strength

Withstand voltage test: Note that the test voltage to wear insulated gloves, respectively, two groups of tests, test time 60S, leakage current 5mA

a.Desk lamp

For SELV voltage of the basic insulation 500V

* When conducting the test, the installation surface is covered with metal foil

1)Between current-carrying parts of different polarity

2)Between current-carrying parts and mounting surfaces

3)Between current-carrying parts and metal parts of the luminaire

b.Power adapter

Double insulation or reinforced insulation|4U+2750V

*Mounting surface covered with metal foil when conducting tests

1)Between current-carrying parts of different polarity

2)Between current-carrying parts and mounting surface

3)Between the charged parts of different polarity that can be made by the action of the switch cannot be flashover phenomenon during the test, let alone the serious bad situation such as leakage by breakdown.

Insulation resistance

500VDG test 60S, insulation resistance requirements: between the positive and negative pole of the lamp, between the positive and negative pole and the installation surface and between the positive and negative pole and metal parts minimum insulation resistance of 1MQ power adapter between the positive and negative pole, between the positive and negative pole and the installation surface minimum insulation resistance of 4MQ

Fire resistance test

The sample (key electrical components) is burned with an open flame at a temperature of 650 degrees 50C for 30S.

Burn 30S, any flame or burning material of the sample should be extinguished after removing the burning wire for 30S. Falling incendiary or molten material should not cause the thin paper laid horizontally under the sample 200mm 5mm to catch fire. (This item is a confirmation test and is tested once every six months)

Outer box

Packing carton size, specifications, paper quality, word mark in line with the requirements of the document; packaging methods without errors, omissions, misloading

The outer box word mark is not clear, overshadowing, skewed phenomenon

No obvious color difference in the outer box (refer to the sample seal)

No crumpling, damage or moisture in the outer box, and the gap between the outer box and the seal should not be larger than 2mm

Color box

Color box size, paper quality meets the requirements, no errors in word mark printing, no errors in packaging methods, omissions, misassembly; complete accessories (manual, installation accessories)

The color box has no obvious color difference (refer to the sample seal)

Color box without crumpling, moisture, damage, cracking phenomenon, color box printing clear, no ghosting

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.