Did Your Clothes Pass the Needle Detector Test?

Everyone in the clothing industry should know that there is a general test: Needle detector test. The simple statement is that the broken needle in the garment will be detected to avoid harming the human body. As early as the 1970s, there was an incident in Japan where there was a broken needle in the textile, causing the child to be injured and killed. Therefore, the Japanese legislated “Needle Inspection Law” ordered all textiles and all wearing items which touched human skin,the detection of sharp metal foreign matter must be carried out before retailing,it was named needle detector test. China has developed a national standard for needle detectors, which is suitable for detecting broken spurs, pins or other ferromagnetic substances left in various types of clothing. In the clothing inspection, needle detector test must be carried out.Because it is close-fitting clothing, after touching the human body, if the broken needle is found, it is extremely harmful.

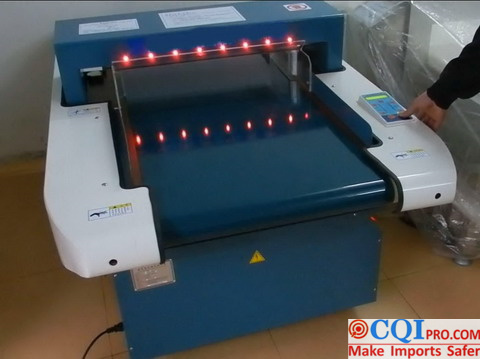

Needle Detector Test Machine

The needle detector machine,it mainly uses in toys, garments, shoes, chemicals, leather, knitting and other industries. They detect needles, pins and iron scraps left in the products to ensure that the products are free of iron filings. Provide the most reliable quality assurance. However, there are still some shortcomings. The principle of the needle detector is the principle of magnetic induction, so only ferromagnetic metals (iron, cobalt, nickel and alloys containing these metal impurities) can be detected, and other high-purity fine tiny metals cannot be detected. If it is a small factory or a small workshop, there may not be a regular needle detector. The Factory Audit article explains how CQI testing can help importers review plant size and equipment.

What Materials Will Cause Needle Detector Test To Fail

According to the regulations, before the production, the accessories and decorations must pass the needle detector first.Then all the large goods pass the needle detector before the product leaves the factory again. Of course, from the needle detector itself, it is a very sensitive machine, the product placed in different directions and different positions may lead to different results and the resulting reaction is also different. However, in the needle detector test, there are many external factors that influence the final result, such as:

- There are broken needles in the clothes (especially the seams of the fabric, the overlap of the fabric or the thicker part of the fold);

- Magnetic foreign matters(metal piece, metal scrap or wire, etc.) is mixed in the filling of the clothes;

- The magnetic body is attached to the conveyor of the needle detector;

- A large number of metal accessories (buttons, rivets, etc.) are seton the clothes, because even if the individual parts meet the needle-detecting standards, the reaction values will rise if combined.

- 5.The printing on the clothes, the influence of the hanging tag, or forgetting to remove the bad identification film, etc. will also cause the needle reaction;

- When performing stone washing and other processing, the metal impurities attached to some of the accompanying materials are attached to the clothes.

Iron metal buttons or zippers, can they pass the needle detector test after demagnetization?

This is a headache that is often encountered in garment factories. The demagnetization refers to the process in which the magnet returns to a magnetic neutral state. Demagnetization is an addition and subtraction operation involving magnetic objects, and the needle detector checks the magnetic components of iron/cobalt/nickel in these articles, rather than checking the magnetic properties of the metal button zipper. Of course, magnetic metal is impossible to pass the needle detector test.

Therefore, the demagnetization can not change the iron metal button, but the purpose of passing the needle detector test can be achieved.Only the raw material can be replaced to make a metal with no magnetic force, such some non-ferromagnetic metals:copper, aluminum or zinc alloy.

Therefore, when testing various products, the needle detector test is for accessories that do not have magnetic metal, otherwise the test will be meaningless.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.