The Real Show of Non-stick Wok Production Process

Non-stick wok production process is mainly divided into three types: stretching wok, imitation die-casting wok and die-casting wok, which are introduced in detail below.

- The first one is a stretching pan, which has a simple manufacturing process and low cost. For making non-stick wok, it is generally made of aluminum sheet by stretching machine. At present, there are many stretching woks in the market, with low price and low production threshold. Family workshops can make it. The wok body is thin, and the bottom of the wok will even deform and bulge after being burned for a long time.

- The second kind is the imitation die-casting wok, the process is generally similar to that of the stretching wok, and the aluminum sheet is also used, except that the aluminum sheet of the imitation die-casting wok is thicker, which is pressed by a forging press, so the cost and threshold are improved, and it can be manufactured by small and medium-sized factories in general. The thickness of the wok is significantly higher than that of the stretching wok, which is similar to that of the real die-casting wok.

- The third is the die-casting wok, the process is relatively messy, and it is necessary to melt the aluminum ingot into molten aluminum and then inject it into the die-casting machine. After the mold is integrally formed, there are no rivets in the wok body. Generally, there are rivets in the wok bodies of stretch woks and imitation die-casting woks, which is also an intuitive way to judge. Common non-stick wok in Europe, with relatively high process cost, thick wok, uniform heating and no deformation. Generally, large factories have the strength to manufacture, and they are mostly used for export.

Non-stick Wok Production Process,the Detailed Flow is As Follows:

Wok shaping

Making woks and pans starts with an aluminum wafer. The ductility of aluminum is very good. After a strong stamping and stretching, the bottom of the deep wok is shaped upwards!

The stamping of the shallow wok is not so exaggerated. Once the manipulator absorbs and flips, it will enter the next process.

Compound wok

The working principle of induction cooker is electromagnetic induction phenomenon. Alternating current generates a changing magnetic field through the internal coil, thus generating eddy current. Joule heat generated by electric current is the heat source of cooking (think of light bulb, which gives off heat and gives off light! ) According to the limitation of magnetic induction and resistivity, iron or stainless steel is the preferred material for the bottom of the wok.

Can’t a single iron or stainless steel be used? Why do you have to make a composite wok with aluminum wok steel bottom? The wok has the smell of wok (also known as the taste of home), and the effect is that the heat is high and the wok smells good. But if the heat transfer is too fast, it is easy to paste the pan. However, the aluminum layer of the composite bottom wok body is not so fast in heat transfer, and the heating uniformity is good, so it is not easy to produce oil smoke.

Cold bottom

One way to compound stainless steel sheets at the bottom of aluminum wok is pure physical riveting.

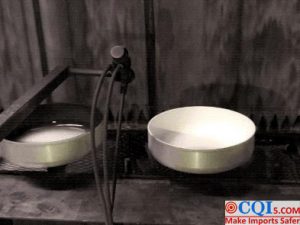

That’s what the bottom of the wok looks like when the cold bottom is finished. All kinds of riveting holes, but it doesn’t matter. It will be polished and leveled later.

The advantage of riveting is that there is no heating process during bonding, which saves the time required for cooling, and it can be directly sent to trim the edges in one go.

Hot bottom

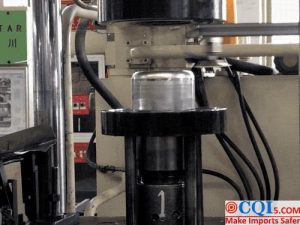

Another method of adding stainless steel bottom to aluminum wok is called hot double bottom. First, the metal surface to be contacted is heated to 500℃. Then send it to the friction press, combine it vigorously, and it’s fresh and hot. This is the bottom of the wok after hot bottoming.

Hard oxidation

Next, add an enchanted attribute-“electroplating” to the wok. Aluminum is easy to oxidize and can react with acid and alkali. Therefore, aluminum wok should be immersed in electrolyte, and a hard anodic oxide film should be plated on its surface to improve corrosion resistance and wear resistance.

Internal surface spraying

The spraying process of non-stick layer is “heating-spraying layer-heating-spraying layer again”. First of all, it is the preheating link before spraying, and the wok must be preheated before it can be better combined with the coating.

The first inner surface painting, an intuitive painting process.

Spray again+heat in the kiln, and the inner surface can be sprayed after many cycles.

Baking and shaping

Finally, before entering the baking tunnel, an aluminum sheet will be placed on the bottom of the wok to prevent the uneven heating in the heating process from deforming the bottom of the wok.

Grinding outer surface

After cooling, it can be sent to the fully automatic grinding of the outer surface.

Manual marking

There is also a process of carefully identifying defects at the polished outlet of the machine. After the defective parts are manually marked, they will be repaired in the next step. Only when the outer surface is perfect can it be sent for spraying.

External surface spraying

Making the outer surface is also a similar process, with cyclic heating and spraying, except that an extra cover is needed to the bottom to prevent spraying on the stainless steel bottom.

Trim the bottom

Before the trimming step, the sizes to be trimmed are reserved, and the bottom edges are trimmed one by one directly on the lathe.

Grind the bottom

Before the cold riveting, now it’s smooth with a grinding wheel.

Trim the bottom

Before assembly, the bottom of the wok needs to be flattened.

Assembly link

Finally, screw on the handle, match the wok cover, wipe it clean, and after strict quality inspection, wrap it in plastic film, put it in the quality inspection mark, and then box it for delivery.

Of course, the non-stick wok production process is only one aspect, which can’t directly explain the quality of the wok. The non-stick wok depends on the technical level of coating and spray coating. At the same time, readers can combine our other article: the inspection standard of non-stick wok, so that they can have a deeper understanding of this kind of products.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.