Plastic Quality Control,The Most Important Raw Material Inspection

There are many kinds of processing techniques for plastic products. Different plastic products have different raw material requirements and processing requirements. Each supplier has different processing techniques and equipment foundation, and even the main points of plastic quality control are different. International importers also have different quality requirements for imported products, and generally choose suitable suppliers according to the characteristics of the products.

Plastic Quality Control-Production Process

After years of development in the plastic industry, the discovery and innovative use of new plastic raw materials and the increasingly rigorous and perfect plastic quality control system, as well as the diversification of its processes to meet the diversification of the structure of finished plastic products, are now basically divided into the following types of plastic processing processes:

Injection molding ( injection molding and die casting ), blow molding, blister molding, compression molding, foaming molding, calendering molding, micro foaming technology, lamination molding, casting molding, drop molding, compression molding, resin transfer molding, extrusion, thermoforming, hand paste molding, laser rapid molding, melt deposition molding, CNC computer digital control machine tool, 3D printing, etc.

Because different plastic products have different process requirements above, to some extent, importers have some doubts about the stability of product production and finished product quality. They worry that if there is a new production demand, the factory will not be able to really grasp the product quality in terms of plastic quality control, or will not be able to provide timely solutions to improve the product quality and cause losses after discovering the product defects.

Plastic Quality Control,Inspection Items

However, there is a Chinese saying called ” changing the soup without changing the dressing”. CQI provides professional and complete custom inspection protocols and product inspection, summarizes the defects of several common types of daily finished products from the QA perspective, and also summarizes the defects frequently encountered by plastic quality control in plastic parts, such as:

- Difficulty in demoulding;

- product surface ripple;

- Rough surface;

- Lack of plastic parts;

- Warpage and deformation of plastic parts;

- Peeling and layering of plastic parts;

- Silver stripes;

- Poor surface gloss;

- Dents;

- Bubbles;

- … …

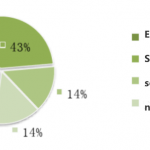

Combined with QA analysis, the above defects may be caused by several categories such as raw material type and purity, raw material temperature, mold temperature, mold size, material heating or cooling time, injection molding parameters, etc. During plastic quality control before shipment, according to the logic sequence of the process corresponding to the cause of the defect of the product, we can almost find out the cause of the defect smoothly, find the problem ahead of time and solve it, thus reducing the losses of both sides of the trade. This is the advantage of outsourcing inspection.

Therefore, importers can check whether the factory has perfect product QA while checking the factory environment and process technology. To do a good job of auditing, importers have more energy to follow up the production progress of plastic products and plastic quality control, and the worries will be reduced a lot later.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.