The Big Problems Found In The Plush Toy Inspection Report

Product:Animal Plush Toys

Inspection Company:CQI Inspection

Inspection Date:11012021

Location Area:Shangdong,China

A.Plush Toy Inspection Report-Remarks

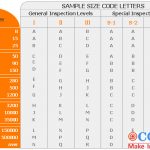

- The factory provided the quantity of this batch: 50400pcs with 504 cartons.When inspector arrived, only 207cartons were packed, the rest products were under packing by workers.

- The PO and toy code showed in the sample size was same,but different from the one given by client.Need to be confirmed.

- The actual carton size and the one showed on shipping mark were different from the carton size given by client.

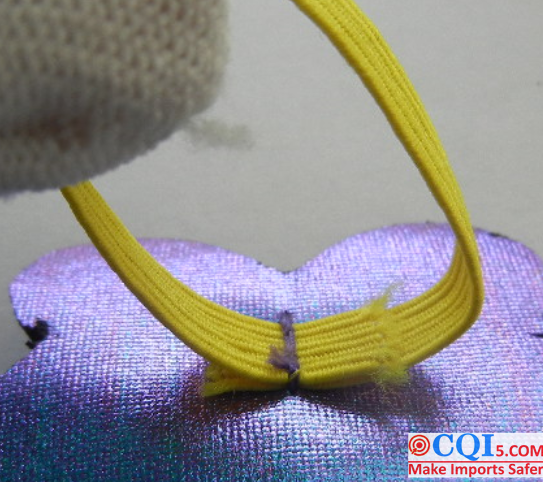

- For all elastic band,frayed yarn was found at the end of it.

- For the harry the hedgehog,actually the animal was sloth.

- The dimension of product was similar with the approved samples, but not consistent with the size given by client)5x6x5cm.

- For some items,the actual carton G.W was out the the tolerance ±5% with the showed on on shipping mark and given by client.

- For the QR code,all could be scanned,but the result needed to be confirmed by client.

- No pantone was available in the factory to check logo during the inspection.

- The name card was not packed with plush toy in each PP bag,but separately packed together.

B.Plush Toy Inspection Report-Defects

1.Untrimmed thread

2.Poor sewing

3.Mismatch

C.Plush Toy Inspection Report-Tests

1.Carton Drop test

2.Pull test

3.Elastic function test

4.Hanging test

5.QR code scanning test

6.Rub test

7.Assembly test

8.Seal test of PP bag

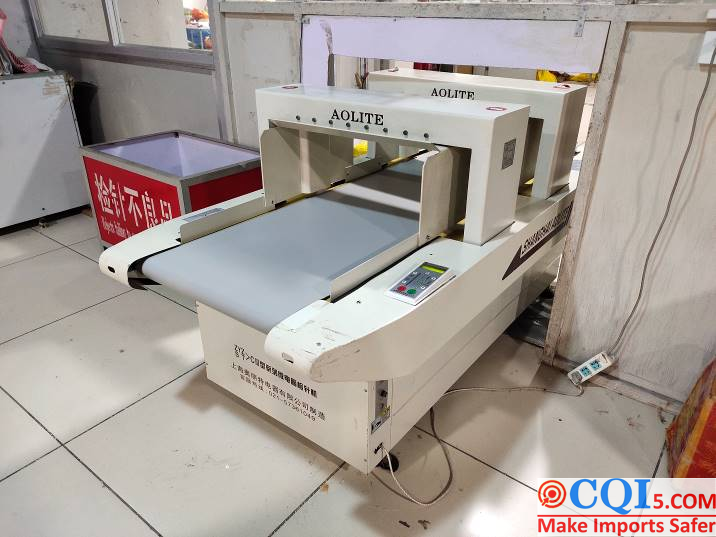

9.Metal detection

10.Inner materials check

11.Accessible sharp Point & Sharp edges check ( if any,)

12.Structure & Workmanship

13.Odor check

14.Cleanliness check