What Is The Sofa Production Process ?

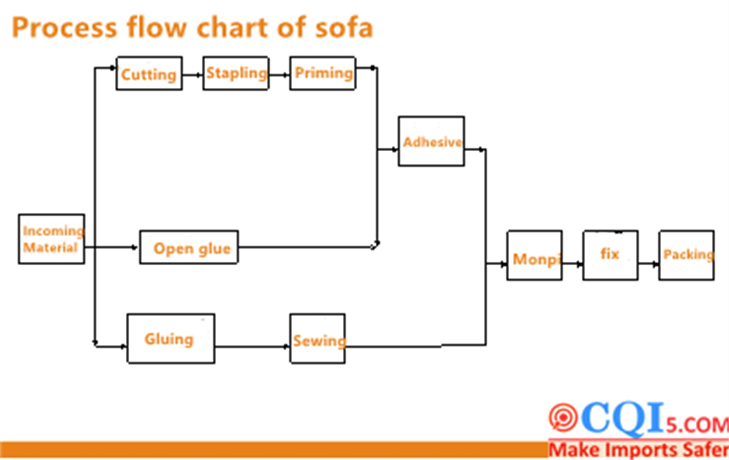

Sofa production process is characterized by the variety of materials used, material differences, making the frame with wood, steel, artificial board, paint, decorative pieces, etc.; filling with sponge, foam plastic, elastic, non-woven, spring, brown cushion, etc.; making the jacket with cloth, leather, composite materials, etc.. The processing technology spans from carpentry work, lacquer work, sewing work to hairdressing work. According to the principle of professional division of labor and improve efficiency, the sofa processing is divided into 5 sections: frame section, the main production sofa frame; external decoration section, the main production sofa exposed components; lining section, with various types of sponge core; jacket section, cutting and sewing jacket; total assembly (leather) section, the semi-finished products of each former section, with auxiliary materials, assembled into a complete sofa products.

We can predict the sofa production process through different sofas will appear poorly , and targeted inspection.

Different sofa production plant its sofa production process is also different, small enterprises process division of labor is rougher, large and medium-sized enterprises process division of labor is more detailed, specialized division of labor is conducive to improving work efficiency and ensure the stability of product quality.

Ingredients Process Of Sofa Production Process

Sofa frame with most of the material is plate, with open saw cut linear plate, small enterprises are cut with circular saw, band saw cut curve type plate. Sofa frame with material can be used MDF, because MDF has the advantages of large width, high rate of material, especially significant for curved parts. At present, a variety of fasteners and connectors with MDF are very good performance. For solid wood out of the frame, handrails, decorative pieces, the surface quality of these parts require high, complex process, some also need solid wood bending, some need special technology processing, such parts are basically consistent with the processing of solid wood furniture, will not be discussed.

Clear and correct ingredient list, scheduling diagrams, curved parts of the template, is the main measure to rationalize the use of materials and improve work efficiency.

Assemble The Frame Of Sofa Production Process

Formulated panels, bending parts, square combination into a frame, and seal the bottom plate. Made sofa frame to pay attention to its quality, the mass production of the frame size to meet the requirements, the size of the error to the total assembly (skinning) process causes trouble. The strength of the frame to meet the requirements of the current sofa frame structure to experience, in fact, through the optimization process can reduce the frame with materials or further improve the strength. Frame structure of the process should also focus on, to facilitate the operation of subsequent processes. The surface of the frame should be treated as light, burrs and sharp corners, in order to avoid leaving hidden problems to the follow-up process.

Sponge Preparation Of Sofa Production Process

According to the specifications of the bill of materials, scribe and cut the sponge, for the complex shape, the sponge to be cut in sets should be attached to the list of materials and templates to facilitate construction.

Paste The Frame Of Sofa Production Process

In the frame nail elastic band, nail gauze, gluing thin or thick sponge for skinning process for the preparation, reduce the amount of skinning process work. This process of the specification of the elastic band, the number, tension value, cross order should have corresponding requirements, these parameters will affect the comfort and durability of the sofa.

Jacket Cutting Of Sofa Production Process

According to the ingredient list requirements, cut according to the sample. The natural leather sheet should be checked one by one, avoiding scars and blemishes. Synthetic materials can be cut into stacks of electric shears, the reasonable use of precious natural leather, the amount of material to choose to use, to eliminate the use of large material. Jacket cutting is a production cost control point.

Coat Sewing Of Sofa Production Process

Cut the jacket, according to the different sofa production process requirements in different sewing equipment sewn into the jacket, cushion cover, etc.. At present, there are many varieties of sewing equipment, sofa stitching is also developing and changing.

Assembly (Skin) Of Sofa Production Process

Will be glued frame, processed inside and outside, a variety of trim, accessories assembled into a sofa. The general process is to nail the frame with sponge on the inner sleeve, and then set the jacket and fixed, and then installed decorative pieces, nail the bottom cloth, installed feet.

Inspection And Storage Of Sofa Production Process

The product can be packed into the warehouse after passing the inspection.

You want to know more about the sofa common defects, sofa inspection standards and related inspection cases, welcome to enter our blog site to check, of course, if you have any questions can always email us.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.