Is The Production Process Of Sports Shoes Very Complicated

The sports shoes production process is mainly divided into the following steps:

1. Production Process Of Sports Shoes–Cutting

Cutting the raw material into cut pieces – the parts of the upper of the shoe. According to different cutting methods, cutting is divided into traditional cutting and automatic cutting. Traditional cutting is mainly done by using traditional cutting machine with chopper and chopper board; while automatic cutting is done by using modern automatic cutting machine, which lays out the parts in the computerized layout system and the cutting head of the cutting machine cuts according to the layout path. Automatic cutting machine than the traditional cutting machine efficiency is greatly improved, the quality is also more stable, but the equipment investment is larger, maintenance costs are higher, generally large shoe factories will only purchase a large number of automatic cutting machine.

2.Production Process Of Sports Shoes–Processing

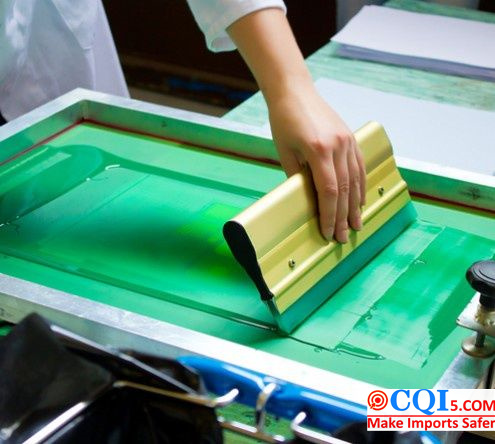

Processing mainly includes printing, electric embroidery, high-frequency, Non-sew (no-turning), etc.

Printing is divided into screen printing and digital printing. Screen printing printing is the process of transferring ink onto the material using a screen, while digital printing is the process of printing ink directly onto the material using a digital printer through a nozzle.

Electric embroidery is a process in which a set pattern is embroidered onto the material with a color thread through an electric embroidery machine to display the pattern.

High-frequency is the process of using a high-frequency machine with a copper die to press the desired logo or pattern through pressure and current to create a convex or concave effect, usually with a printing process to bring out the three-dimensional effect of the logo or pattern.

Non-sew technology is a technology that adheres different materials together by heat pressing instead of stitching.

3.Production Process Of Sports Shoes–Needle turning.

Needle-turning is the process of sewing different parts and cut pieces together on a needle-turning machine to produce a shoe upper.

4.Production Process Of Sports Shoes–Bottom-gapping.

The sole plus is the process of bonding the sole components together with a treatment and glue.

5.Production Process Of Sports ShoesShaping

Shaping is a very important step in the Sports shoes production process, where the turned upper and outsole are glued together with a treatment and glue.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.