Sportswear Process Inspection,Avoid Being Cheated By Factories

Sports clothes are clothes specially used for sports competitions or outdoor sports activities. Sports clothes suited for sports competitions are designed and made according to the specific requirements of sports events. Sports clothes for ordinary outdoor activities are mostly casual clothes. In daily life, the material of sportswear is also various. Because the main function of sportswear is moisture absorption and perspiration, many manufacturers are using the fabric of chemical fiber products, most of which are polyester. By increasing the capillary effect of the fiber itself, sweat on the surface of the human body can quickly diffuse through the clothing, evaporate into the air, do not stay on the skin, and keep the clothing dry and comfortable.

Of course, importers should choose fabrics according to the specific market plan, because fabrics involve the amount of exercise, sweat discharge, environment and form of exercise, which is more complicated. In the sportswear process inspection, it can help importers to further confirm fabrics and prevent factories from cutting corners.

Understand The Production Process Before Sportswear Process Inspection

Selection of raw materials – confirmation of size, color and accessories – cutting – sewing – quality inspection – primary ironing – secondary ironing – labeling – sorting and packaging

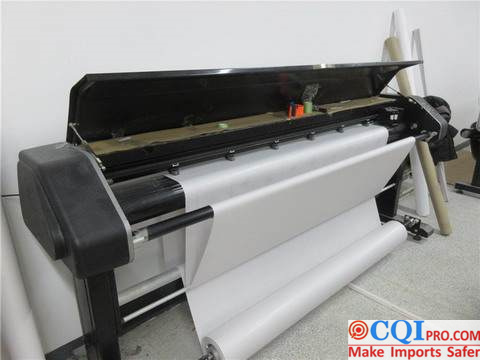

1.Clipping

According to the design drawing of the product, cut the cloth. Pay attention to the same batch of products to keep the same shape and size and different sizes should meet the customer’s requirements, otherwise the product size will be inconsistent. Cutting is generally divided into three types: plane cutting, three-dimensional cutting and prototype cutting.Factories usually cut in batches through clothing cutting machines, electric punching machines and electric scissors to ensure the consistency of products.

2.Sewing

All cut pieces will be sewed according to the product design drawing. Stitching and sewing needles of different materials are also required. For some harder materials, sewing needles are required to be thick enough, otherwise,there will be broken needles,which will endanger human health.

3.Ironing

In the previous process, the product will form certain wrinkles and indentations, and the product will be restored to a smooth state by ironing, which will facilitate the subsequent packaging and labeling. In the process of ironing, we must pay attention to the temperature control. Too low or too high is not conducive to the shaping of the product and may even scald workers.

The Impact Of Manufacturing Process On Sportswear Process Inspection

1.Impact of cutting operation

The size of the same size has deviation.The size interval of different sizes has deviation.The product has many thread ends, poor trimming and poor appearance quality. In the first step of sportswear process inspection, inspectors should pick out products with cutting defects so as not to affect the quality of the whole batch of large goods.

2.Influence of sewing process

When the sewing quality is not good, the sewing result may appear as sewing thread jam, seam wrinkling, thread breakage, jumper, thread breakage, etc. When the sewing needle quality is not good, pinholes,uneven needle spacing and even broken needles will appear in the sewing position of the product.

3.Influence of ironing process

The defects caused by ironing are an important part of sportswear process inspection and also the core process of clothing products. If the temperature and time of ironing are not well controlled, the product will suffer from scorching, yellowing, whitening and wrinkle recovery. Moreover, if the product is not cleaned before ironing, stains will remain after ironing.

Importers may find that every process is indispensable in the sportswear process inspection, and workers’ operation must be standardized on the production line of the factory, otherwise the products will suffer from major defects or even serious defects. In this case, if the importer wants to confirm the production of the goods and it is not convenient for him to check personally, it’s best for him to arrange during production inspection of CQI inspection. Because in the middle of product production, each process can be inspected and effectively avoid the occurrence of subsequent quality problems.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.