What Will Happen To The Supply Chain Layout Under The Epidemic

The epidemic is a human disaster, but it is also an opportunity to transform and upgrade the global industry chain. Some industry insiders believe that if the experience of the outbreak can serve as a wake-up call for companies, it also has the potential to advance the establishment of a more flexible, reliable and shock-resistant supply chain layout globally.

“COVID-19 is currently having no impact on the global food supply chain, but the situation could soon get worse if anxiety-induced panic in major food-importing countries prevails.” The World Food Programme said on April 6.

At a time when the new coronavirus outbreak continues to spread around the world, the impact on the global supply chain has become one of the hot topics of public opinion.

Supply Chain Layout-Repositioning Trends

How will the global supply chain be impacted? Since the outbreak, there has been a lot of discussion about this issue.

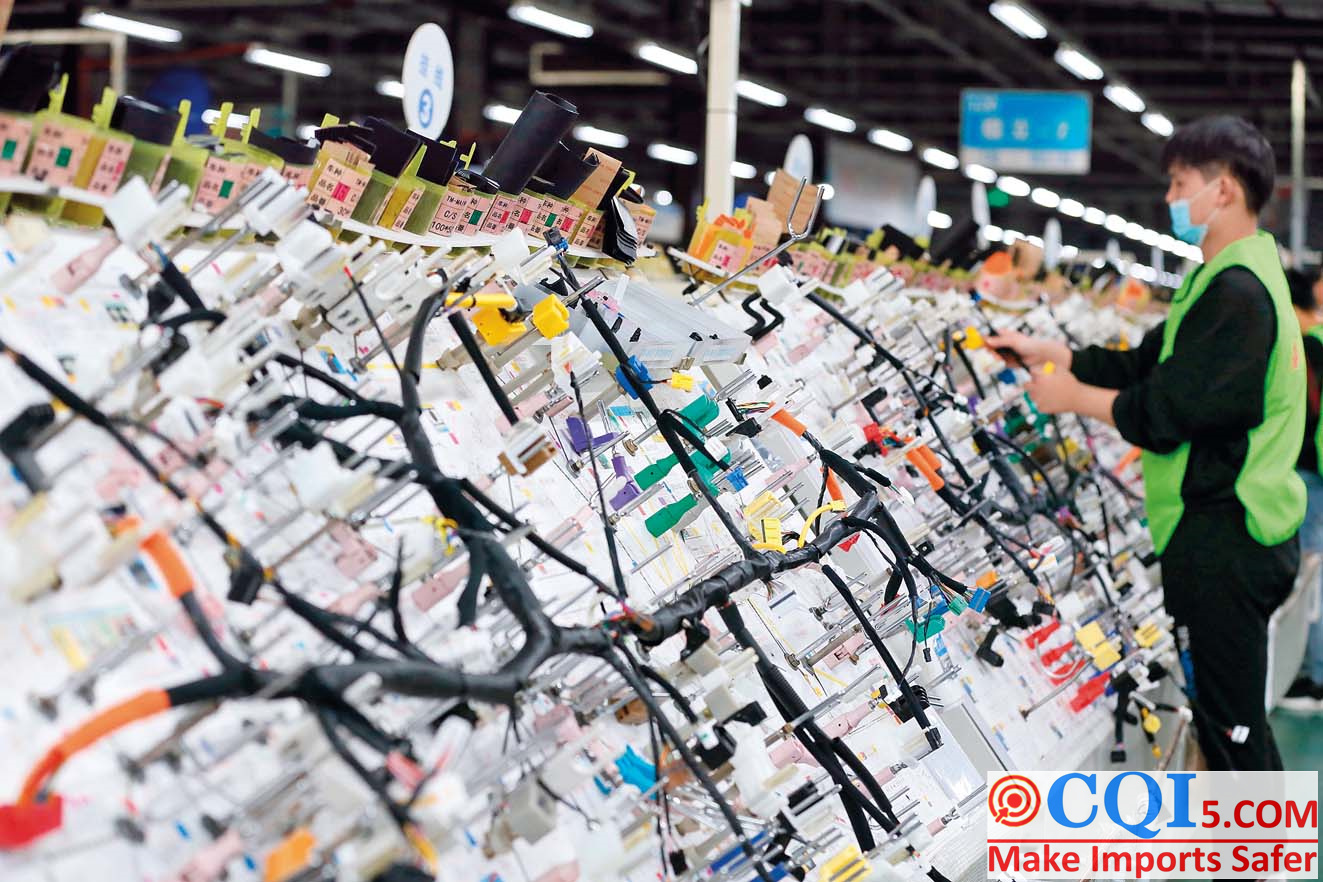

According to a study published by Dun & Bradstreet, 163 of the Fortune 1000 companies have Tier 1 suppliers – direct business contacts – in China, and another 938 have Tier 2 suppliers in China that supply Tier 1 suppliers. This means that if there is a product that only one factory can produce, if anything happens, the entire production line will be affected.

Now that the outbreak is tentatively under control in China, the global spread of the outbreak is still a cause for concern. The global automotive, electronics, retail, and financial industries, as well as the entire service sector, including tourism and restaurants, have been significantly impacted by the COVID-19.

According to Huang Qunhui, director of the Institute of Economic Research, Chinese Academy of Social Sciences, the impact of the epidemic on global supply chains may go through three stages: First, after China’s supply chain presses the “pause button”, certain links of the global supply chain are affected; second, as the epidemic spreads, overseas supply chains are blocked and demand falls back, which in turn affects the Chinese industrial chain; third, the global supply chain faces the risk of disruption. Third, the global supply chain is at risk of disruption.

The topology of the GSC, i.e., its shape, pattern, and connectivity, will determine how the supply shocks triggered by the new crown pneumonia epidemic will affect global production, said Jeffrey Goetz, a research fellow at the Global Economic Governance Program at the University of Oxford. “The real threat is that production stagnation may expose previously unknown choke points in the global economic network.”

Imagine this scenario: each product will go through multiple stages such as raw materials, processing, packaging, transportation and distribution before reaching the final consumer, and each stage may include different way such as sea, rail, air and land transportation. It can be said that the global supply chain is interwoven, just like a huge net. The absence of any one of the key nodes may lead to the paralysis of the entire network.

Fu Xiaolan, director of Oxford University’s Technology and Management Development Research Center, told the Globe magazine that, influenced by economic and trade frictions and other impacts, there have been cases of multinational companies repositioning global supply chains and shifting some production to other countries. “The new technological revolution has driven the use of industrial robots and artificial intelligence, reinforcing the trend of supply chain return. This outbreak, in turn, has intensified the trend of global supply chain repositioning.”

Gauke Eiding, a professor at Johns Hopkins University’s Kelley School of Business, holds a similar view. He believes that the COVID-19 may accelerate a trend that has already emerged: global manufacturers will become more risk-aware and avoid relying on suppliers in only a single country, instead diversifying their supply base.

Supply Chain Layout-Towards Diversification, Digitalization and Transparency

The epidemic is a human disaster, but it is also an opportunity to transform and upgrade the global industry chain. Some industry insiders believe that if the experience of an epidemic can serve as a wake-up call for companies, it also has the potential to advance the establishment of a more flexible, reliable and shock-resistant supply network globally.

In the view of Nick Vyas, executive director of the Center for Global Supply Chain Management Research at the University of Southern California, the future re-integration of the global supply chain will show several characteristics, such as closer to the location of consumer demand; more diversified sources of supply; low cost is no longer the only consideration, and so on.

According to Xiaolan Fu, considering various uncertainties, enterprises will pay more attention to diversification, intelligence and localization when laying out their supply chains in the future, and will pay more attention to investment in technology and other intangible capital to improve their core competitiveness. Overall, it will further promote the global supply chain to be more resilient and flexible, with stronger ability to withstand risks.

She stressed that through this epidemic, we can see that traditional supply chain management has reduced the efficiency and flexibility of the whole operation, and in the future, the industrial Internet system based on digitalization, networking and intelligence will make the supply chain system more fast and flexible.

In terms of increasing supply chain resilience measures, Benny Mantin, director of the Center for Logistics and Supply Chain Management at the University of Luxembourg, suggests using the outbreak as an opportunity to improve supply chain transparency, such as trying dual sourcing and information sharing, and for companies to be clear about where the parts they need come from in order to better hedge their risks. At the same time, governments have a role to play in the process.

So, will the future realignment of global supply chains, especially the trend towards diversification and localization, affect China’s position in the overall chain?

In an interview with Global magazine, Oxford University professor Golding said that factors such as the development of automation and 3D printing technology, shorter delivery times for goods, and personalization of goods will drive companies to produce closer to their markets. Although the trend of globalization may be weakened in some places, the focus of future globalization will shift to Asia, especially China, because it has “a huge, fast-growing market that continues to attract global investment and will become a powerful engine for future global economic development.

Challenges and opportunities

Under the impact of the epidemic, the global supply chain is facing huge adjustments. Some industry insiders believe that this is both a challenge and an opportunity for China, seizing the opportunity to promote the industry chain to further modernization and high-end.

Mao Xuxin, chief economist of the UK National Institute of Economic and Social Research, analyzed to the Global magazine that under the impact of the epidemic, the transaction method will shift from the traditional paper documents and meeting and exchange to be done online, and there are high requirements for data sharing, transmission platform and confidentiality technology in this process, and China has good development in this area, and if it can continue to strengthen the development of blockchain and other technologies in the future, it can have good conditions.

On how China should respond to the impact of global supply chain diversification, Huang Qunhui believes that, on the one hand, for key industries, key industrial links and key core enterprises, China should promote the localization and regionalization of the supply chain; while for general industries, links and enterprises, it should promote the diversification and digital transformation of the supply chain and improve the security level of the industrial chain.

In this regard, Fu Xiaolan also holds a similar view. She believes that there should be planned trade-offs and creations based on factors such as industrial added value, importance, local adhesion, environmental protection and energy conservation, for example, 100 billion public health care products, digital technology and artificial intelligence, and new economy industries such as telemedicine services should be considered for greater development.

At the same time, it is necessary to promote high-quality development around the manufacturing industry, so that the level of modernization of China’s industrial chain and the value chain to climb up to the high-end, and occupy a more favorable competitive position in the global supply chain.

“It is also necessary to create an environment for factors to gather and enhance the “adsorption stickiness” of the global value chain.” By strengthening R&D and design capabilities, logistics and infrastructure support capabilities, and training of skilled workers, and building a first-class business environment with internationalization, rule of law and facilitation, the adhesion of multinational companies’ production links to local factors will be enhanced, said Fu Xiaolan.

Huang Qifan, vice chairman of the China Center for International Economic Exchanges, believes that China should accelerate the “attraction of capital to replenish the chain” and focus on building a number of strategic emerging clusters with high spatial concentration, close upstream and downstream synergy, intensive and efficient supply chains, and a scale of hundreds of billions to trillions of dollars in the Guangdong-Hong Kong-Macao Greater Bay Area, Beijing-Tianjin-Hebei, Yangtze River Delta, and Chengdu-Chongqing twin-city economic circle. industrial chain clusters.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

Disclaimer:

CQI5 article information from the Internet and contributions, the copyright of which belongs to the original author, and only represents the views of the original author. This website is only responsible for sorting out, typesetting and editing the articles, reproduced for the purpose of spreading more information, does not imply that it endorses its views or proves the truthfulness, completeness and accuracy of its content, and therefore does not assume any legal responsibility.

The information contained in this article is for reference only and is not intended as direct advice for decision-making.

If we inadvertently violate your copyright, please inform us, after verification, we will immediately correct or delete the content according to the requirements of the copyright holder, thank you! Contact, email: copyright@cqipro.com

This website has the final right to interpret this statement.

Welcome to reprint, please be sure to keep information complete.