Umbrella Process Inspection,Make Sure The Quality

Umbrellas are generally divided into three categories,for rainy days, for sunny days, and both for rainy and sunny.On materials, oil paper, tarpaulin or plastic cloth is usually used. With the improvement of the quality in daily necessities, umbrellas are not only a tool to cover the rain and snow, but also a kind of decoration.Many kinds of umbrellas give more inspirations to customers.Wanting to let consumers buy practical and fashionable umbrellas, it needs a help from the umbrella process inspection. When the inspectors help professional umbrella importers to verify the quality of the products, the quality of the whole batch of large goods is guaranteed.

Umbrella process

Raw material preparation – cutting – umbrella printing – splicing – mounting umbrella beads and umbrella surface treatment – installing ribs – mounting accessories – quality inspection – packaging

1.Cut

The cut is divided into a big cut and a small cut. The big cut is to cut a roll of umbrella cloth into a long strip shape (three fold umbrellas can be cut into three pieces), this step can be done with a cloth cutter or a worker with a blade, then the cloth strip is taken to the edge.(Preventing the umbrella cloth from leaving the yarn), this is the completion of the big cut.The small cut is to cut the strips of the big cut into pieces, as the umbrella surface of the umbrella. The worker first makes a triangular wooden frame with some wooden strips, places the wooden frame on the umbrella cloth, and carefully cuts it with a blade.In the umbrella process inspection, the inspector must check whether the edge of the piece is threaded, otherwise it will directly affect the smooth progress of the subsequent process.

2.Umbrella printing

In the production of umbrellas, silk screen, offset printing and digital printing are basically used.Among them,silk screen printing is most commonly used. First, a stencil is made by a drying machine, and then the stencil is fixed on a square wooden frame.The worker will pour the paint into the wooden frame, then cover the wooden frame on the triangular umbrella cloth, sweep it with oil for a few times, and the pattern will be printed on the umbrella cloth.This process will further identify the mishandled semi-finished products in the subsequent umbrella silk screen inspection.

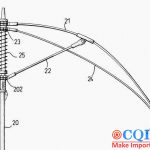

4.Install the ribs

The umbrella surface is joined to the rib, and the worker must connect the umbrella surface to the rib by hand. No machine can be used. On each rib, the worker usually tightens the rib and umbrella surface with two or three knots.

3.Combination

After the silk screen is finished, the triangle piece can be stitched into a canopy. Different types of umbrellas, the number of triangles on the umbrella surface are different, from 6 to 24 pieces.

The impact of manufacturing processes on Umbrella Inspection

1.The impact of the cutting process

In the case of small cuts, each piece must be the same size, except for special designs. The edge of the triangle piece must be manually processed by the worker to complete the hem. If the hem effect is not good, it’s difficult to perform the stitching of the adjacent two triangle pieces at the time of splicing.Moreover,it can not escape the requirements of the umbrella process inspection.

2.The impact of the splicing process

The splicing is a manual sewing of each triangle piece. The stitch length is tight and the number of stitches is sufficient. The purpose of this is to prevent water seepage.Therefore, in the umbrella process inspection,the stitch length and the number of stitches of the splicing sheet must be measured in detail. Avoid importers receiving complaints from consumers.

3.The effect to install the umbrella bead and rib

Umbrella beads are important accessories for umbrellas and are used to fix the umbrella surface with the ribs. The rib can be said to be the most important part of the umbrella. Without it, the umbrella is just a piece of cloth. Therefore, the material of the ribs must be firm and strong.Besides,it also needs the rust-proof treatment.

The focus of the umbrella process inspection involves every link, not just the final inspection of the finished product. The professional umbrella importer cares about the results of the on-site inspection and also pays great attention to the laboratory test project because the quality of the product will affect the management of the supply chain, and even a series of risks of the product.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.