Wooden Floor Inspection,Importers Will Have More Choices

With the improvement of consumer concept, consumers’ requirements for product quality are no longer limited to the appearance of products and the requirements for quality are getting higher and higher. A good product can not decorate the house to make it warm and beautiful, but also protect the health of family members to avoid troubles. The products introduced today are Wooden floor that can be seen everywhere in the home life. It is strong, wear-resistant, stain-resistant and easy to clean, reflecting the simplicity and artistic feeling of the product, making the home environment wide and clear. For the importer, to make the consumer satisfied, wooden floor inspection is the final difficulty to ensure the quality. Once any problems are detected, there is time to ask the factory to rework.

Wooden Floor Inspection,Start Testing With Features

After the importers purchase the products, in order to ensure that the products and the samples are consistent, the third party will be given a wooden floor inspection before shipment.We can understand from several important aspects, such as appearance, wear resistance, stain resistance and heat resistance.

1.Appearance check

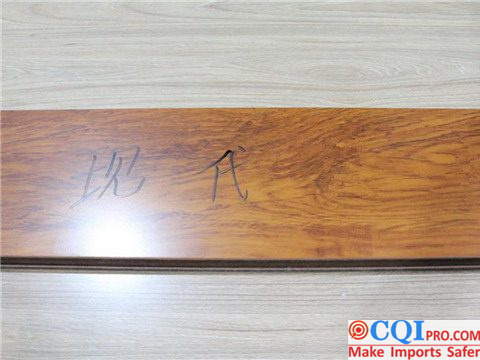

Wooden floor,because it is a natural material, the tree’s annual rings and textures can often form a beautiful picture, giving people a feeling of returning to nature and simplicity. No matter the texture is unique, it is deeply loved by consumers. However, it should be noted whether there are obvious knots and gaps. Although the trees can’t avoid dead knots, when the factory chooses raw materials.

Each piece of wooden floor is sized to assemble and transport. Some products have a special “V” rabbet design that allows each floor to seamlessly interface. Through the actual measurement, the thickness of the wooden floor is 12.24mm, and the slim thickness can be easily applied to various scenes.The texture of the wood is restored from the inside to the outside, and the texture is more complete.

The horizontal rule is placed on the surface of the wooden floor and tests it in all directions.Even with multi-angle measurement,the bubble tube is still level, which proves that the surface of the wooden floor is extremely flat. So what is the problem with uneven wooden floors? The first is the product that partially arched up, which directly leads to uneven installation and uneven ground.It will affect consumers’ use.Products that are tilted up on both sides of the horizontal direction, maybe because they are placed in the warehouse for a long time and the moisture is serious.Such products should also be rejected.Therefore, in the wooden floor inspection, the flatness of each board must be tested.

2.Pollution resistance test

For consumers who regularly maintain their home environment, the most important concern is the stain resistance of the floor. The floor is stain-resistant and can save a lot of trouble for cleaning. It is applied to the floor with a water-based pen and pigment, and then wiped with a rag without any cleaning agent,the writing is easily erased without any trace.

3.Heat test

“True gold is not afraid of fire”, a good product should be tested in all directions, and the wood floor has strong heat resistance. Using a lighter for testing, it was found that there were no signs of burning, bubbling or cracking on the surface of the floor, and the surface was still crystal clear.

4.Wear test

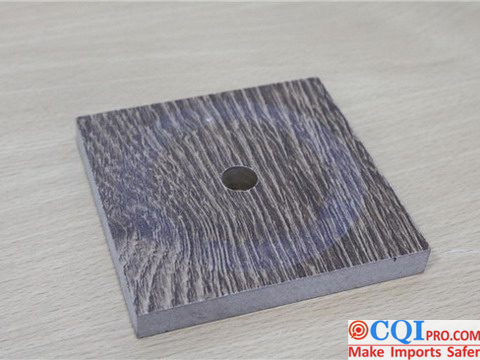

The abrasion resistance of the floor is required to be carried out in the laboratory. Using a professional instrument, test to pass 60 revolutions for 10 minutes,totally 6000 revolutions.After the test,it can be found that the wooden floor does not have any break and it is still intact, which greatly guarantees the wear life of the ground. It is comfortable, durable and not easy to slip with a higher safety factor. Such wear-resistance tests are to be done in the wooden floor inspection on site, which is on the premise that the factory has professional equipment.

5.Environmental test

The lower the formaldehyde content is, the higher the requirements for the raw materials, production technology and processing technology of the factory are required. It often only the technological leaders in the industry can do better.Of course, regular manufacturers will send the products to the laboratory for testing. A test report will show whether their products meet environmental requirements. Therefore, during the wooden floor inspection process, we will ask the factory to show the test report and confirm which batch of the product was submitted.

Through such a wooden floor inspection, including the above four aspects of testing, the wood floor performance is good, the factory selection and process also play an indispensable role, which doesn’t mean the uncracked wooden floor is a good product. When importers choose wooden floor, they must reasonably select factories and arrange third-party inspections on the premise of defining the consumer market. By outsourcing inspections to third parties, not only can product quality be ensured, but also more time and cost can be saved. In the article of Advantage Of Outsourcing Inspection,it describes how the CQI can help importers develop more cost-effective suppliers or optimize the supply chain, and get more profit and better quality from the procurement process.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.