After Covid-19, There is a Global Crisis

“Can’t find the item you want in the shop? You’re not alone.” So reported by USA Today on 15 October on the recent shortage of goods in the United States.

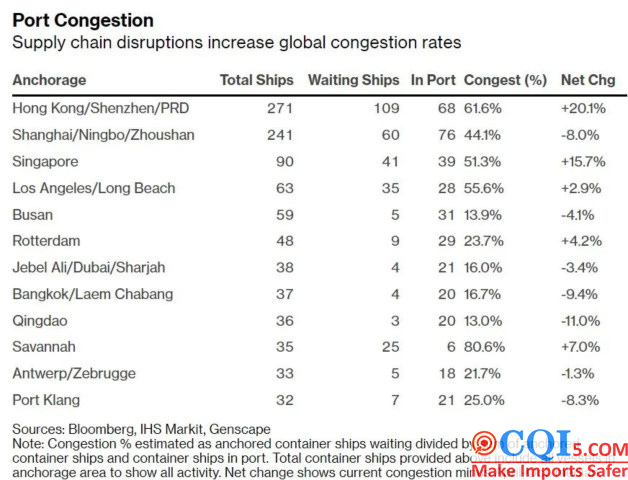

It is reported that the impact of the COVID-19 epidemic on the global supply chain is intensifying, the world faces a supply chain crisis, with many ports becoming more congested and goods piling up, which may ruin the coming Christmas holiday economy, further erode the profits of enterprises and push up the prices of consumer goods.

David Dreyfuss, an assistant professor in the Global Supply Chain Department at Rutgers University’s School of Business, said in an interview that countries around the world are facing both long-term and short-term challenges in their supply chains under the epidemic, but the challenges will vary depending on where each country is in the supply chain. To address supply chain challenges, countries need to focus on the short term as well as the long term.

Global Crisis : Difficulties With Shortages of Goods and People

Recently, KFC in the US ran out of chicken to fry, Korean fast food chains ran out of fries for a long time, the UK Christmas shopping season shortage of goods was brought forward, and labour shortages in Vietnam, Malaysia and Thailand …… The supply chain crisis that has rippled across the globe has left several countries short of goods and people.

Southeast Asia, a key link in the global supply chain, is experiencing a shortage of the labour needed to produce goods due to embargo measures imposed by the backlash against the epidemic. According to the Business Insider website, the expected shortage of workers in Southeast Asian countries such as Vietnam, Malaysia and Thailand could cause logistical delays in cross-border shopping this Christmas, which would cause major problems for retailers ahead of the holiday season.

And South Korea may be in a food supply chain crisis. According to an article published in the English magazine Haps Korea Online, South Korea is experiencing a wave of shortages of imported ingredients due to supply chain disruptions caused by global maritime logistics capacity constraints and other factors during this period. Most McDonald’s shops in Korea are out of stock or short of fries, frozen strawberries, pickles, cream and other foods that sell well on Korea’s online e-commerce platforms have been out of stock frequently recently, and some restaurants specialising in Vietnamese rice noodles have run out of ingredients.

Also troubled by the food supply chain is the United States. CNBC reported that KFC in the US said it had decided to temporarily cancel advertising for boneless chicken due to a shortage of the product. Wingstop, the fast food restaurant famous for its “fried chicken wings”, has also been forced to develop a new chicken leg product to replace its wings due to a massive shortage, while Pepsi will also issue a price increase warning due to a shortage of drink bottles.

28 September 2021 local time ,the UK government is considering military deployments to speed up fuel deliveries, yet the oil giant is still struggling to maintain supplies.

Ports in several countries around the world are also experiencing congestion due to a shortage of truck drivers and containers. As the global economy recovers from the epidemic, manufacturers are using large numbers of containers to transport goods, but these containers are left stranded at ports such as Los Angeles in the US, where dock workers are on leave and truck driver shortages are adding to port congestion.

In ports around the world, ships fail to load and unload containers quickly. Without containers, cargo cannot be transported. Without truck drivers, it is impossible to unload containers containing goods for re-delivery.

Many Reasons Behind the Global Crisis

There are a number of reasons for the current supply chain tensions, with the COVID-19 epidemic profoundly affecting the state of the global supply chain.

Specifically, people are no longer travelling as much as usual due to the impact of the COVID-19 epidemic, and purchasing patterns have changed, with travel spending now remaining contained at pre-epidemic levels, but consumer demand for electronics and other goods has increased. The shortage of raw materials and components for goods like electronics has further led to a shortage of products as manufacturers are unable to invest in production to meet consumer demand.

The COVID-19 epidemic is causing people around the world to work, study and spend their free time at home, driving demand for consumer electronics, according to data from online statistics site Statista Research. However, many electronics remain in short supply due to a global shortage of chips and supply chain disruptions.

Analysis by the Wall Street Journal and other foreign media suggests that the sharp increase in consumer demand also stems from the recovery from the economy in many countries around the world and the arrival of the Christmas shopping season. Since the epidemic situation has improved in October, more and more people in Japan have shown interest in buying cars, and residents of the US and UK are preparing to purchase Christmas goods in advance.

However, according to the Wall Street Journal, global industry consultant AlixPartners said that the global automotive industry will cut production by 7.7 million units worldwide due to the chip shortage, close to 10% of projected production in 2021.

According to the Sun newspaper, a large number of people flocked to shopping malls and retail outlets in the UK over the past week to buy toys and gifts, driving an increase in traffic to various stores. They are buying gifts more than a month to two months earlier than in previous years, with the total number of customers increasing by nearly 5% per week. The British Retail Consortium recently warned of a shortage of Christmas presents this year and predicted that the supply chain crisis could continue until April next year.

In addition, a shortage of containers, insufficient truck capacity and a shortage of workers prevent commodities from being delivered to their intended destinations as they normally would be.

“Once the products are produced, logistics providers will rush to transport them. But with schools closed due to the epidemic, and children needing care and childcare being expensive …… multiple factors have led to a shortage of workers such as truck drivers, making it difficult to keep the global supply chain running smoothly.”

The data shows that a large amount of cargo is backed up at multiple ports, with the US East Coast port of Savannah, Georgia having 25 ships waiting late on Thursday compared to only 6 in port, with congestion at 80.6%, the most of any major port. And on the West Coast, the neighbouring ports of Los Angeles and Long Beach had more ships waiting than in port, with a cumulative congestion rate of 55.6 % on October 15.

The CEO of MGA Entertainment, the world’s largest privately owned toy company, thinks “the US Christmas season is over this year” because “you can’t get the labor, you can’t get the trucks, you can’t get the merchandise out. “

The Atlantic published an article on 7 October analysing that the supply chain crisis currently facing the US is the result of a combination of domestic and global factors. In addition to the global COVID-19 epidemic, factors such as an outdated US domestic road and rail freight system and a six-fold increase in trans-Pacific transport costs over the past year as demand surges have also contributed to the supply chain crisis in the US.

Short and long-term measures needed to get out of supply chain rut.

On 13 October local time, CNN quoted a recent report by international credit rating agency Moody’s as saying that supply chain disruptions across global industries are pushing up consumer prices and slowing the global economy’s recovery from the COVID-19 epidemic.

In a report released on the 11th, Moody’s said that the problem of supply chain disruptions could “get worse”. ABC quoted supply chain experts as saying that the best option for consumers now is to wait and start to gradually reduce demand for goods, otherwise they may have to pay higher prices once these long-awaited products are available.

In the face of the current supply chain crisis, many countries are taking great care and taking action.

US President Joe Biden announced in a speech on 13 local time that the ports of Los Angeles and Long Beach, two of the largest ports in the US, will be operating 24 hours a day, seven days a week, to address port cargo congestion and allow mainland US cargo trucks to deliver goods at night when traffic is lighter.

The UK, which is also in a supply chain crisis, argues that it is important for the UK to adopt a long-term strategy to deal with it. According to the Independent, the UK government has suggested that it should invest in training staff for the UK freight industry, rather than relying on migrant workers.

It is the peak time for the production of Christmas goods and the South East Asian country is trying hard to encourage workers to return to work. The Vietnamese government is reportedly providing transport and companies are raising wages and benefits, but so far with little success.

On how to deal with the supply chain crisis, countries said that getting out of the supply chain dilemma requires both a short-term focus and a long-term perspective.

In the short term, businesses have to get creative to find workarounds and customers have to be patient or find their own workarounds. Some companies are now attracting talent through incentives such as higher wages, others are chartering ships and planes to deliver goods rather than waiting for their usual suppliers, and customers are exploring alternative suppliers wherever possible.

“The problems faced by manufacturers and logistics providers will be solved over time, but it may take one or two years. Training more workers and implementing automation where possible will help overcome some of these problems.” David said.

In the longer term, companies should map their processes to better understand their current bottlenecks and know who is responsible for which piece to manage risk more effectively. In addition, the management of the business and its suppliers and customers should be more integrated, which will help minimise the impact of future supply chain disruptions.

Disclaimer:

CQI5 article information from the Internet and contributions, the copyright of which belongs to the original author, and only represents the views of the original author. This website is only responsible for sorting out, typesetting and editing the articles, reproduced for the purpose of spreading more information, does not imply that it endorses its views or proves the truthfulness, completeness and accuracy of its content, and therefore does not assume any legal responsibility.

The information contained in this article is for reference only and is not intended as direct advice for decision-making.

If we inadvertently violate your copyright, please inform us, after verification, we will immediately correct or delete the content according to the requirements of the copyright holder, thank you! Contact, email: copyright@cqipro.com

This website has the final right to interpret this statement.

Welcome to reprint, Please be sure to keep information complete.