Do You Know The Details Of The Non-Stick Pan Inspection Standard?

Purpose

ements of CQI Inspection Company for Non-stick pan , this non-stick pan inspection standards requirement is specially written to standardize the company’s quality inspection service level for customers

Scope Of Application Of Non-Stick Pan Inspection Standard

This inspection technical document is used to standardize the pre-shipment inspection service of Non-stick pan .

Defect Definition Of Non-Stick Pan Testing Standard

Serious defects (CRT): the user’s life is a major hazard or has the potential to harm and violate the relevant safety requirements of defects

Major defects (MAJ): affect the use of the product, reduce product reliability and service life or seriously affect the product image defects

Minor defects ((MIN): the product has a slight appearance defects and does not affect the product function defects

Standard Grade Of Non-Stick Pan Detection

Sampling standards: MIL-STD-105E

Acceptance level (AQL): CR=O MA=1.5 MI=4.0

Common Defects Of Non-stick Pan Inspection Standard

(1) Non-stick pan material defective items

①Size / shape / color / material does not meet the requirements

(2) Non-stick pans packaging defective items

①Moist / moldy

②Package products are mixed / wrongly packed

(3) Accessories are not complete

④Sticker error/leakage/position does not match

⑤ plastic bags without printing / perforation

⑥Mark/printing error/leak

(4) The packing requirements do not match

(5) Non-stick pan appearance / bad process items

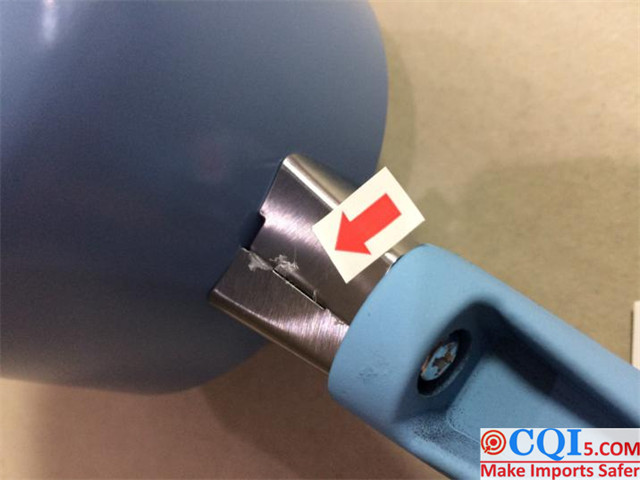

①Batch edge / edge gap (can lead to human injury)

②Uneven thickness

③ stain / oil / water / rust stain

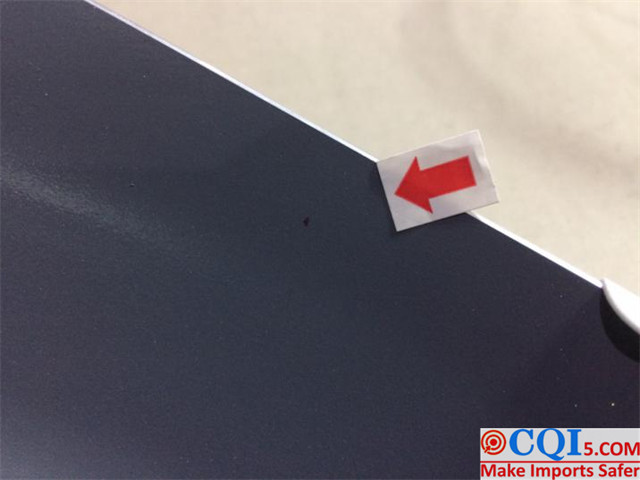

④Rough surface / surface scratches / rust, oxidation

⑤ color difference / uneven brightness

⑥Crack / fracture / dent / pulling body lines

⑦ Non-stick pan handle off / ring welding mouth off

⑧ product deformation / bending / screw slip teeth / loose / leak

⑨ bad welding: solder joint false welding / batch peak /

⑩ poor polishing: planing light dark shadow / excessive creation of light / planing light bad

(6) Non-stick pan-related test defects

①Corrosion test is bad

②Bad handle test

③Drop test defect

④Other test defects

(7) Non-stick pan-related measurement defects

①Dimensions do not meet the requirements

②Bad barcode scanning

Common Testing Items For Non-stick pan Inspection standards

(1) appearance inspection: product appearance inspection should be in normal light using the hand, visual inspection, stainless steel body surface roughness inspection according to GB/T10610 (surface roughness using comparative inspection for inspection).

① Appearance should not have serious drawing marks, pockmarks and polishing unevenness caused by the light difference.

②In addition to the knife, the edges of various products should be free of scraping and stabbing.

③The surface is smooth, no obvious drawing marks, no dents. No sharp edges, prickly hair phenomenon.

④Welding parts are firm, no cracks, and no scorching, thorn phenomenon.

⑤Packaging methods and other aspects in line with the contract requirements.

For polished products.

①No wax oil, handprints, dirt in the pot.

② whether the bottom grinding bottom is ground in place, the punch is placed squarely against the positioning, the internal paint can not be beaten.

③Polished products must have brightness, illuminated portrait.

④ internal paint can not be blistered, less oil impurities, bruises, scratches

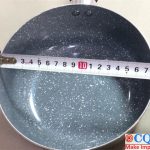

(2)non-stick pan weight size: against the drawing, the thickness of the container allowable deviation plus or minus 0.2 mm, the bottom thickness allowable deviation plus or minus 0.4 mm,

The allowable deviation of diameter, height and depth are plus or minus 2% of the standard size.

①non-stick pan Capacity: If there is a declared capacity, the actual capacity shall not be less than the declared capacity.

② non-stick pan diameter: the claimed bottom diameter and the actual measurement of the average of the two bottom diameters (vertical direction) deviation should not exceed + / – 10 cm; the claimed other diameters and the actual measurement of the average of the two diameters (vertical direction) deviation should not exceed + / – 5 cm

(3) Corrosion resistance test: the product is immersed in water loaded with sodium chloride concentration of (50 ± 5) × 10-6, and maintained at 22 ± 4 ℃ for 16 hours, in the product surface, under normal visual inspection should be no corrosion generated.

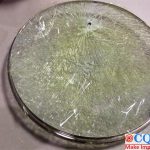

(4) coating adhesion test: test the coating special adhesive paper paste coating surface, press the adhesive paper and leave 5 cm long at the end; hold the end of the adhesive paper force to quickly tear the adhesive paper in the direction of 90 degrees, with a new adhesive paper repeated stick and tear once

(5) Lid assembly test and structural test requirements: the lid should be tightly nested on the cookware and can be freely rotated; the lid should not fall off when the product is in a 45 degree angle position.

(6) Pot stability test: empty pots and pans with lids in the most unfavorable position on a 5-degree slope (unless the product design excludes this requirement)

(7) Handle connection strength test: Stabilize the pan to a rigid surface and apply a force of 100 N vertically to a single-handled pan or long-handled pan at 10 mm +/- 1 mm from the end of the handle, and a double-handled pan at the same time with a force of 100 N to the end of both handles; see the degree of bending after one minute

(8) Drop test: drop the cookware (pots and pans) from a height of 1m to the concrete floor with the handle vertically downward for 5 times, and then drop the cookware (pots and pans) in the horizontal direction for 5 times

(9) plastic handle high temperature softening test: the main body of the product will be placed in the pot of water to maintain 100 ℃ ± 4 ℃, the same material made of plastic handle any part of the pot on the heater, the heater to maintain a constant temperature of 110 ℃ ± 2 ℃, for 6 min after the bending degree.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

Disclaimer:

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.