Let’s Take a Brief Look at the Toy Standard in Different Countries

Toys play an indispensable role in children’s growth. However, there are unsafe factors in some toys, and children’s resistance to external aggression is not as good as that of adults. Therefore, toys need to be tested, and only products that meet the standards are marked, otherwise they are not allowed to be produced, sold or imported.

Nowadays, countries all over the world attach great importance to the safety of children’s toys, and they have formulated and continuously improved the testing regulations for children’s toys. The manufacturing technology of toys in China is relatively mature, and the export areas are mainly the United States, Japan and Europe. For export toys, let’s take a brief look at the toy inspection standards in different areas:

Toy standard in China : GB6675

At present, China’s toy safety standard is GB6675-2003 (national toy safety technical specification), which is a national mandatory standard. In terms of technical requirements, ISO8124-1:2000 (safe mechanical and physical properties of toys), ISO8124-2:1994 (safe burning performance of toys) and ISO 8124-3: 1997 (specific elements of toy safety) On May 6th, 2014, China Quality Supervision Bureau and National Standards Committee released the latest edition of GB6675-2014 national standard “Toy Safety”. The new toy safety standard strengthened the safety and quality standards of toys sold in China, which was officially implemented on January 1st, 2016. The new standard is applicable to toys and materials for children under 14 years old to play with. The new standard has four new provisions on toy safety, as follows:

1. basic specification of gb6675-1

The basic safety requirements, such as electrical safety, hygiene and radiation conditions, are summarized.

The specific requirements of six plasticizers were added.

2.GB6675-2 Physical and Mechanical Properties

A new standard on prevention of hearing loss has been added.

Specific requirements for magnets and magnetic parts have been added to prevent the damage of magnetic parts and materials caused by children’s ingestion.

3.GB6675-3 Flammability revised the specific provisions on the specifications and testing methods of stuffed toys.

The “regulations on the flammability of molded masks in whole or in part” and “regulations on the flammability of related floating objects on head-mounted toys” were added, mainly to make specific requirements on their burning speed.

4. The provisions of GB 6675-4 on the migration of specific elements expand the scope of transportable harmful substances, as follows

All toys for children under 72 months.

Applicable to all toys used for food or contact with the mouth, cosmetic toys and writing tools belonging to toys, regardless of any age group or recommended age mark.

Applicable to accessible coatings, accessible liquids, gels and pastes, regardless of any age group or recommended age mark.

GB6675 standard is applicable to all toys, that is, all products or materials designed or intended for children under 14 years old to play. In terms of “mechanical and physical properties”, toys in China are similar to those in the European Union.

GB6675 mainly includes: mechanical and physical properties, combustion performance, specific elements of the migration toy logo and instructions.

Toy standard in EU : EN71

There are 11 parts in the EU toy standard EN71. Generally, toys only need to make the first three parts, namely EN71-1, EN71-2 and EN71-3. China is a big country in toy production and export, and many toys are exported to the European market. All businesses must consciously do the EN71 test of EU toys. Only toys that pass the EN71 test can be allowed to enter the European market.

EN71-1: 2005 Toy Safety-Part 1: Physical and Mechanical Properties

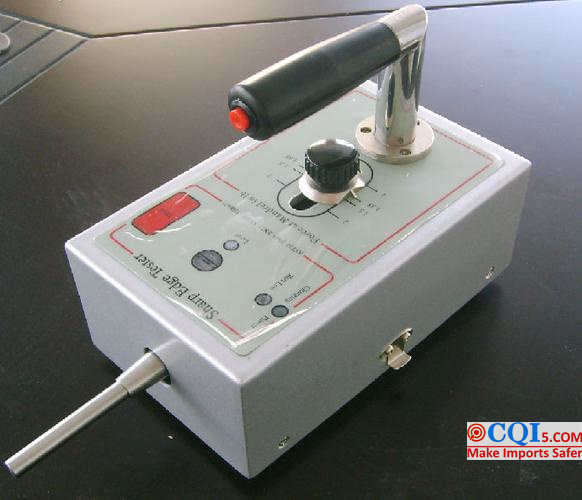

This part mainly includes drop test, small part test, sharp edge test, tension test, pressure test, seam test, otorhinolaryngology tension test, torsion test and so on.

EN71-2: 2006 Toy Safety-Part 2: Flame Retardant Performance

This section specifies the types of flammable materials prohibited for all toys and the requirements for the combustion performance of some toys with small fire sources. It is required that the burning rate of the tested material should not exceed the limit specified in the standard. It relates to toys worn on the head, toy costumes and toys for children to wear in play, toys for children to enter, soft stuffed toys containing plush or textile fabrics.

EN71-3: 2001/AC: 2002 Toy Safety-Part 3: Transfer of Some Elements

This section specifies the maximum limits of transportable elements (antimony, arsenic, barium, cadmium, chromium, lead, mercury and tin) in accessible parts or materials of toys. The testing principle is: soluble elements are dissolved substances extracted from toy materials under the condition that simulated materials are continuously contacted with gastric acid for a period of time after swallowing. The content of soluble elements was quantitatively determined by a method with appropriate detection limit.

Toy standard in America: ASTMF963

ASTM F963 “Toy Safety” is the most important toy safety standard in the United States, and it is also a toy safety standard with great international influence. This standard is a voluntary and non-mandatory standard. Although it is a voluntary standard, in commercial practice, toys that do not meet ASTM F963 cannot enter the American market.

This standard makes technical requirements and test methods for toys used by children under 14 years of age. This standard covers the dangers that may not be easily recognized by the public and that toys may encounter after normal use or reasonably foreseeable abuse. This standard only stipulates the safety performance of toy products, but does not involve the performance and quality of toy products. In addition to the functional hazards of toys pointed out in the label requirements and the age groups for which toys are suitable, this standard also does not require the inherent and recognized dangerous parts in toys as functional functions, such as the tip is inherent in the function of needles.

ASTM F963 is formulated according to the mandatory requirements of federal regulations in the United States. Generally speaking, the standard fully contains the relevant technical requirements of CPSC 16CFR. Manufacturers can ensure that the products meet the requirements of ASTM F963, which basically meets the relevant technical requirements of CPSC 16 CFR. However, in order to ensure that the products meet the requirements of CPSC 16 CFR, Toy manufacturers should pay attention to the requirements of CPSC 16 CFR and its changes in time while ensuring that the products meet the requirements of ASTM F 963, so as to ensure that the products meet the requirements of American laws.

The main technical requirements of ASTM F963 include mechanical and physical safety, combustion performance, chemical toxicity, electrical safety and microbial safety.

International Toy standard: ISO8184

ISO (International Organization for Standardization) is a worldwide international standardization organization (ISO member organization). The drafting of international standards is generally carried out by ISO technical committee. After the completion of the standard, it needs to be circulated among the members of the technical committee for voting, and at least 75% of the votes can be officially promulgated as an international standard.

International standard ISO8124 was drafted by ISO/TC181, Toy Safety Technical Committee.

ISO8124 includes the following parts. The general name is toy safety:

Part 1: Safety standards for mechanical and physical properties

The latest version of this part of ISO8124 is ISO 8124-1:2009 updated in 2009. The requirements of this part apply to all toys, that is, any products or materials designed or clearly indicated or used for children under 14 years old to play.

This section specifies the acceptable judgment criteria (basis) for the structural characteristics of toys, such as sharpness, size, shape, clearance (such as sound, small parts, sharp edges and edges, hinge clearance), as well as the acceptable judgment criteria for various special performances of some toys (such as the maximum kinetic energy of the inelastic projectile at the end and the minimum included angle of some riding toys).

This part specifies the toy requirements and testing methods for children of all ages from birth to 14 years old.

This part also requires that some toys or their packages be marked with appropriate warnings and instructions for use. Due to the different languages in different countries, the words of these warnings and instructions are not specified, but the general requirements are given in Appendix C.

This part does not indicate that it covers or includes the potential harm of various special toys or toy types that have been considered.

Ex. 1: A typical example of sharp injury is the sexual tip of a needle. The needle injury has been recognized by the buyers of toy sewing kits, and the functional sharp injury is notified to users through normal education, and warning signs are marked on the product packaging.

Example 2: Toy syringes also have related and recognized injuries in use (such as instability in use, especially for beginners) and potential injuries with structural characteristics (sharp edges, clamping injuries, etc.), which should be reduced to a minimum according to the requirements of this part of ISO8124 standard.

Part 2: Flammability

The latest version of this part of ISO8124 is ISO 8124-2:2007, which was updated in 2007. This part explains in detail the types of combustible materials prohibited for toys and the flame retardant requirements for specific toys when they come into contact with tiny fire sources. Regulation 5 of this part specifies the test method.

Part 3: Migration of Specific Elements

The latest version of this part of ISO8124 is ISO 8124-3:2010 updated on May 27th, 2010. This part mainly controls the heavy metal content of accessible materials in toy products. This update did not change the specific limit requirements of the standard, but made the following adjustments in some non-technical aspects:

1) The new standard specifies the range of toy materials to be tested in detail, and expands the test range of surface coating on the basis of the first edition;

2) The new standard adds the definition of “paper and cardboard”;

3) The new standard changes the test reagents used for oil removal and wax removal, and the changed reagents are consistent with the latest version of EN71-3;

4) The addition of the new standard indicates that the uncertainty should be considered when quantitative analysis is made to judge whether it meets the requirements or not;

5) The new standard revised the maximum inhalable amount of antimony from 1.4 μ g/day to 0.2 μ g/day.

Toy standard in Japan: ST2016

In 1971, Japan Toys Association (JTA) established Japan Safe Toys Logo (ST Mark) to ensure the safety of children’s toys aged 14 and under, which mainly includes three parts: physical and mechanical properties, flame retardant properties and chemical properties.

The ST 2016 version released this time is mainly revised for the physical and mechanical properties of the first part: 1. Comprehensively revise the relevant clauses of ejection toys; 2. Add new requirements for some extrusion toys, rattles, fasteners and other toys and toy parts; 3. Design principles for bath toys; 4. Define the control standard of the battery.

The control standard of the second part of the flame retardant performance is updated to ISO 8124-2:2014.

The chemical properties of the third part are consistent with ST 2012, and the new requirements have been implemented since January 1, 2016, and the test methods and standard solutions have been revised. Please refer to the annex for details.

As of March 31, 2016, Japan Toy Association (JTA) also accepted ST 2012 or ST 2016 as the standard of ST certification mark. From April 1, 2016, all ST certification applications must comply with the safety requirements of ST 2016, while the existing ST Mark identification information conforming to ST 2012 can be used until March 31, 2018.

It can be found from the above toy testing standards of different countries that most of them are mainly divided into three categories: physical properties, chemical toxicity and flame retardance of toys. Its main contents are similar, and it provides standard requirements for the safe production of toys.

As a third-party quality inspection company, CQI not only inspects the quality of goods for customers on the spot, but also cooperates with different laboratories in the industry to arrange large samples for standard laboratory tests. If you need to know what tests and quotations your toys need to do, you can contact us. We will choose the most suitable scheme for you based on our professional comparison.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you.