What Exactly Is The Production Process Of Water Purifiers?

Do you know what is the Water Purifier Production Process?At present, most tap water meets the relevant drinking water standards when it leaves the factory. However, in the process of transportation, it may be “secondary polluted” because of the aging of pipelines, untimely cleaning of water tanks in residential areas and other reasons. Therefore, the impurities contained in tap water discharged from water valves at home usually exceed everyone’s imagination. Therefore, in order to better protect the safety and health of drinking water, many families will choose to use water purifiers. Therefore, the choice of water purifiers is very important. If you want to choose a suitable product to solve this problem, you must first figure out its principle. So what is the Water Purifier Production Process?

Common Water Purifier Production Process

With the progress of science and technology, the production process of water purifier is constantly changing. Manufacturers optimize and improve the water quality and filter substances, but the main processes are generally as follows.

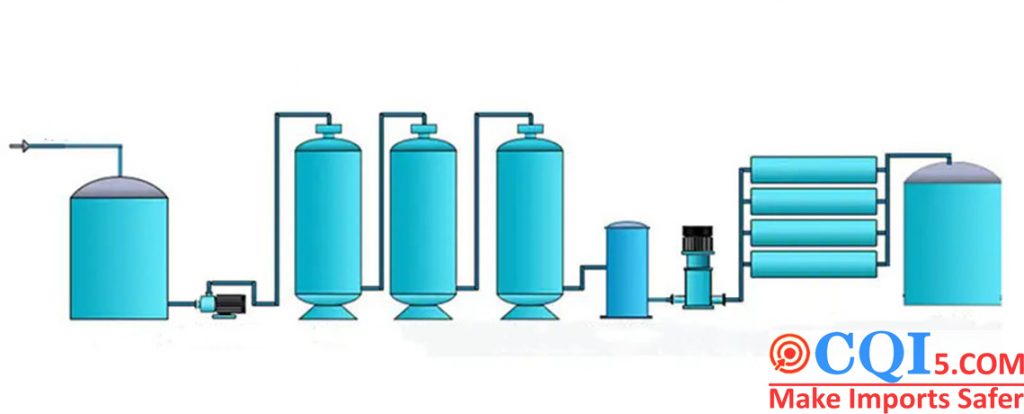

Process 1: Quartz sand+activated carbon+softening system+security filter+reverse osmosis device.

Process II: Quartz sand+activated carbon+scale inhibition system+security filter+reverse osmosis device.

Process III: flocculation and sedimentation+quartz sand+activated carbon+scale inhibition system+security filter+reverse osmosis device (applicable when raw water is poor).

Process IV: Quartz sand+activated carbon+softening+security filter+reverse osmosis device+ozone sterilization/ultraviolet sterilization (for pure water production and beverage preparation).

Process V: Quartz sand+activated carbon+softening equipment+security filter+primary reverse osmosis+secondary reverse osmosis+ozone sterilization/ultraviolet sterilization (applicable when the conductivity of raw water is more than 1000μS/cm).

The Water Purifier Production Process Used In Different Places

Water purifier production process in mineral water plant:

Raw water → raw water pressurizing pump → activated carbon filter → automatic water softener → precision filter → hollow ultrafiltration device → stainless steel water storage tank → ozone generator → purified water pressurizing pump → precision filter → filling line.

Water purifier production process in tap water plant:

Multi-media filter → activated carbon filter → resin softening system (or dosing system and PH adjustment system) →5 micron precision filter → reverse osmosis host system → ozone sterilization system → purified water tank → filling line (or water point).

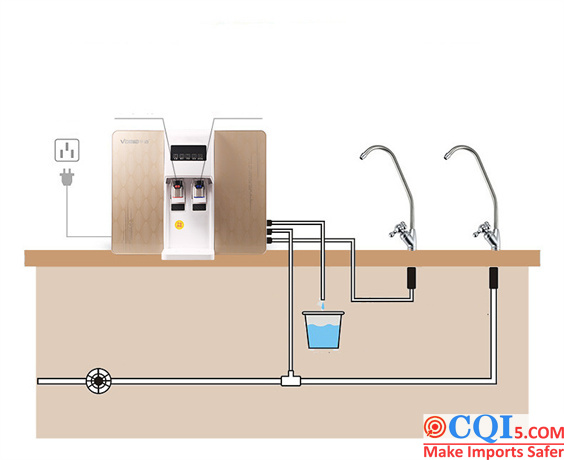

Water purifier production process in home or office:

Tap water-→ water purification equipment-water dispenser (coffee table \ kitchen, etc.)

Water purifier production process in other public places:

Tap water (or well water is pumped to the water tank) → Central water purification equipment 1+ultrafiltration water purification equipment-water storage tank-+pipeline-+water dispenser (straight drinking tap)

For example: unit \ school \ hospital \ community \ hotel

Filter Of Water Purifier Production Process

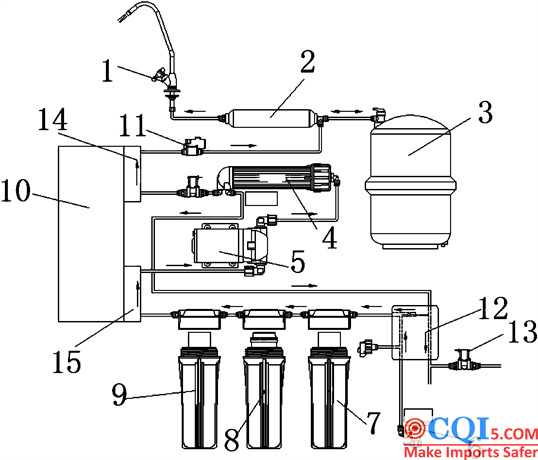

Filter membrane and activated carbon are the foundation of the water purifier, and a key step of the water purifier’s workflow is its filter device. So what are the filters of the water purifier?

Water purifier production process-activated carbon filter

Activated carbon water purifier uses granular activated carbon, powdered activated carbon or compressed activated carbon as water purification medium. Because of its developed micropore structure, it has a high specific surface area, and can adsorb a variety of organic substances and heavy metals to remove odorous substances in water. More than 80% of water purifiers are mainly activated carbon filters.

Water purifier production process-multi filter

Activated carbon filters are often used in combination with other filters to enhance water purification efficiency. Some add copper-zinc alloy filters in front of activated carbon filters to remove residual chlorine in water and inhibit bacterial reproduction; Some front polypropylene melt-blown filter elements are used to remove suspended substances in water; Some are equipped with silver-infiltrated activated carbon and rely on silver ions for disinfection; There is also the addition of ultraviolet sterilization to enhance sterilization effect.

Water purifier production process – ultrafiltration

Ultrafiltration is a membrane process of separation under the action of pressure difference, which can intercept bacteria, macromolecules, colloids, etc. At present, the domestic ultrafiltration water purifier is mainly based on the combination of activated carbon and ultrafiltration membrane.

Water purifier production process -nanofiltration

Nanofiltration and ultrafiltration have the same principle, except that the diameter of nanofiltration membrane is 1~2 nm and that of ultrafiltration membrane is 1.5~100 nm. Therefore, the rejection rate of nanofiltration is higher than that of ultrafiltration. Household nanofiltration water purifiers are generally used with activated carbon.

The above is the introduction of the production process of the water purifier. Do you understand it all?

If you want to know more about the production process of different products and related inspection cases, please visit our blog website. Of course, if you have any questions, please feel free to let us know by email.

CQI5 is committed to providing importers worldwide with product quality inspection services that far exceed those of our peers. If you are planning to import or have imported from China or Southeast Asian countries, please contact us cs’@’cqipro.com to learn more about how we can make your imports safer.

This article is an original article for CQI Inspection, who is committed to providing high-quality product inspection technology and know-how sharing for global importers and retailers to make imports safer.

All rights reserved. The contents of this website provided by CQI Inspection may not be reproduced or used without express permission.

For reprint, please contact with CQI Inspection, thank you