Appearance Check in Electric Blanket Inspection Standards

1.Size

1) Determination of flexible parts and heating area size of appliances

Lay the appliance on the table without obvious stretching, and measure the size of the measured appliance with a measuring tool, and the reading is accurate to 10 mm.

Measurement of length and width: four width values are measured evenly in the direction perpendicular to the length, and three length values are measured evenly in the direction perpendicular to the width, and the arithmetic average values are taken respectively.

2) Determination of the size of the detachable cover

Measure the size of washable removable cover to evaluate the washing effect. The measurement method shall be implemented according to 7.1.1.

3) Determination of flexible cord length

Under the condition that the power cord and connecting line are not obviously stretched, measure the length of the flexible cord from the point where it enters the flexible part of the appliance (including the inlet sheath) to the point where it enters the power plug sheath (excluding the sheath) with a measuring tool. The length is expressed in millimeters (mm), accurate to 10 mm.

2.Quality

The quality of flexible parts is measured after testing in Chapter 10.

Measure the mass of the appliance after electrifying it at rated voltage for 3 hours, and the mass per unit area is calculated by dividing the mass by the area offlexible parts. The mass per unit area is expressed in grams per square meter (g/m), accurate to 10 g/m.

Note: The quality of flexible wires and other external components is not included

3.Composition of textiles

The fabric composition of the outer surface of the flexible part and the detachable cover (if any) shall be marked by marking.

Requirements for Temperature in the Electric Blanket Inspection Standards

4.Temperature uniformity

Measurement of temperature uniformity of heating area.

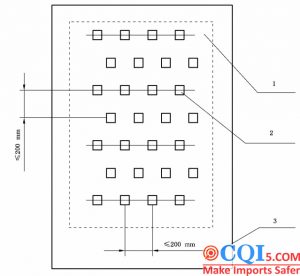

The temperature of the heating area is measured by thermocouple. The diameter of thermocouple shall not exceed 0.3mm.. If the controller is adjustable, the test shall be conducted and calculated when the controller is placed in the maximum position and the minimum position. Thermocouples should be welded on 25 mm×25 mm×0.5 mm copper or copper sheets, which should be alternately placed on and between the heating elements, and fixed by sewing or other suitable methods. When measuring, make the side of the copper sheet without temperature sensing element contact with the use surface of the appliance (the side close to the user in normal use). The test points should be arranged in the effective heating surface of the appliance, with the number of test points not less than 16. The test points in the length and width direction of the heating surface should be evenly distributed. The distance from the center of the copper sheet at both ends of the length to the edge of the heating surface is half of the distance between the test points in the length direction, and the distance between the test points should be no more than 200 mm (see below photos)

The temperature rise is measured after the steady state is established.

For the electric blanket, electric cloak and electric quilt with the upper cover, the copper sheet should be placed under the flexible parts.

For the lower electric blanket, the copper sheet should be placed on the flexible parts.

Measure the temperature of each point and calculate the average value, then subtract the room temperature as the temperature appreciation. The temperature range is determined by the difference between the maximum temperature rise and the minimum temperature rise.

The consistency calculation is expressed by the percentage of the ratio of the number of test points in the heating area with the average temperature rise within ±2 K to the number of all measurement points in the heating area.

Temperature uniformity is expressed by temperature rise range and consistency. The range of temperature rise is expressed as k, accurate to 1K. Expressed as a percentage of consistency, accurate to 1%.

Note: For electric blankets with high temperature areas, the temperature uniformity of each heating area should be calculated separately.

Note: The temperature uniformity of non-uniform electric blanket is not measured.

Photo 1 schematic diagram of temperature sensing element distribution

Description:

1-Heating area;

2-Copper or brass sheet;

3-Electric blanket.

5.Heating time and energy consumption

Determine the heating time of the appliance. Determine the energy consumption during heating time and during working. If there is a standby setting on the controller, also determine its energy consumption.

Under the test condition of (15 2)℃, the appliance should be preset in this environment for at least 24 hours.

When the appliance controller is set to the highest temperature position, it is energized to work, and when the temperature rises to 15K, the required time is recorded.

Measure the energy consumption during the heating time. Then adjust the controller to the highest temperature setting for continuous use, run the appliance for 8 h, and measure the energy consumption.

Measure the input power according to Chapter 5 of GB/T 35758—2017 when the appliance is in standby mode. The temperature rise is measured by the copper plate described in Chapter 8, which is placed in the center of the heating area. Mark the heating time to the nearest minute.

The energy consumption in heating time and complete working cycle is expressed in watt-hours (w h), which is accurate to the nearest w h. If applicable, indicate the standby power according to Chapter 6 of GB/T 35758—2017.

6.Temperature stability

Determine the temperature stability of controlled instruments.

Under the condition that the environment is kept at (20 1)℃, the appliance controller will work in the continuously used gear; if not, it will work in the lowest gear. Until the steady state is established, measure the temperature rise according to Chapter 8, and calculate the average temperature of the heating area.

If the appliance can’t work under this condition, lower the ambient temperature until the appliance can work.

Then the ambient temperature decreases by (10 1) K, and the average temperature is calculated after the steady state is established.

Temperature stability c is calculated according to formula (1):

![]()

Ti, T2-ambient temperature;

S1——the average temperature of the heating area at the ambient temperature t1;

S2——the average temperature of the heating area at the ambient temperature t2.

Temperature stability is expressed as a percentage, accurate to 1%.

Other Requirements of Electric Blanket Inspection Standards

7.Washing effect

Determine the washing effect of washable utensils in size.

Or its detachable cover is washed three times according to the manufacturer’s instructions, and then the size is measured.

Shrinkage s is calculated according to formula (2):

![]()

Type:

A1—the area of flexible parts or detachable covers;

A2 —— the area of flexible parts or removable covers after washing.

The shrinkage rate is accurate to 1%.

Note: If the value of s is negative, it indicates that the appliance is elongated.

If the manufacturer recommends alternative washing methods, the effect of each method should be tested separately on a separate appliance.

8.Controller settings

Different function settings of the controller, such as temperature, timing and program settings, are marked by identification.

9.Factory sampling inspection

Appearance

Size, shape and tolerance

Power cord length

Control device

Sign

Electric shock protection

Input power and current

Generate heat

Leakage current and electrical strength at working temperature

Humidity resistance

Leakage current and electrical strength

Mechanical strength

Internal wiring

Power connection and external cord

Heat-resistant, flame-resistant and electric leakage mark-resistant

In electric blanket inspection standards , not all tests need to be completed in the laboratory. The services provided by third-party inspection companies mainly start with factory testing of these items, and then check whether the products meet the basic use again. In addition, we will start with electric blanket bad reviews collected on e-commerce websites, in order to be closer to customers’ needs and further reduce the risk of complaints in advance.